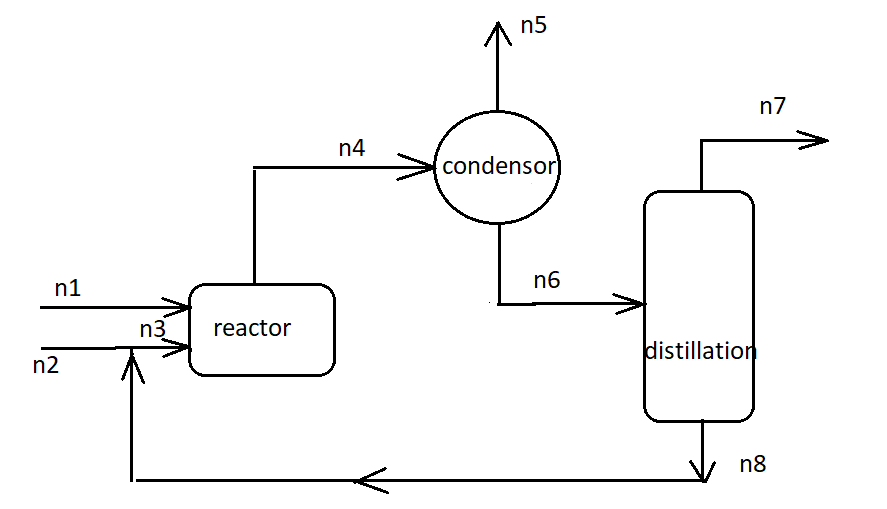

One of the ways that benzene is produced on a large scale is the hydrodealkylation of toluene. CH₂CH3 + H₂ ->>> • CoHo +CH_ A stream of toluene is mixed with a recycle stream and enters a reactor along with a stream of pure hydrogen. The reaction products at 550 °C enter a condenser, where they are cooled to 43.0 °C. A vapor stream containing YSCH, = 0.530 mol CH₂/mol leaves the process, and a liquid stream containing x6b = 0.740 mol benzene/mol and x6 = 0.260 mol toluene/mol enters a distillation column. The distillate of the column leaves the process at n = 781.0 mol/h and contains y7b=0.9300 mol benzene/mol and y7= 0.0700 mol toluene/mol. The bottoms of the column contains X8b = 0.240 mol benzene/mol and x8t = 0.760 mol toluene/mol and is recycled back to the fresh feed. Hydrogen is fed into the process at n₁ = 1710 mol H₂/h. This process is carried out at 760 mmHg.

One of the ways that benzene is produced on a large scale is the hydrodealkylation of toluene. CH₂CH3 + H₂ ->>> • CoHo +CH_ A stream of toluene is mixed with a recycle stream and enters a reactor along with a stream of pure hydrogen. The reaction products at 550 °C enter a condenser, where they are cooled to 43.0 °C. A vapor stream containing YSCH, = 0.530 mol CH₂/mol leaves the process, and a liquid stream containing x6b = 0.740 mol benzene/mol and x6 = 0.260 mol toluene/mol enters a distillation column. The distillate of the column leaves the process at n = 781.0 mol/h and contains y7b=0.9300 mol benzene/mol and y7= 0.0700 mol toluene/mol. The bottoms of the column contains X8b = 0.240 mol benzene/mol and x8t = 0.760 mol toluene/mol and is recycled back to the fresh feed. Hydrogen is fed into the process at n₁ = 1710 mol H₂/h. This process is carried out at 760 mmHg.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Please post the steps!

![**Hydrodealkylation of Toluene for Benzene Production**

One of the ways that benzene is produced on a large scale is through the hydrodealkylation of toluene. The chemical reaction involved is:

\[ \text{C}_6\text{H}_5\text{CH}_3 + \text{H}_2 \rightarrow \text{C}_6\text{H}_6 + \text{CH}_4 \]

A stream of toluene is combined with a recycle stream and introduced into a reactor along with a stream of pure hydrogen. The reaction occurs at 550°C. The products then enter a condenser where they are cooled to 43.0°C.

- The vapor stream contains:

- \( y_{\text{CH}_4} = 0.530 \) mol CH₄/mol

This vapor stream exits the process, and a liquid stream, with the following composition, enters a distillation column:

- \( x_{6\text{B}} = 0.740 \) mol benzene/mol

- \( x_{6\text{T}} = 0.260 \) mol toluene/mol

The distillate from the column exits the process at \( n_7 = 781.0 \) mol/h with:

- \( y_{7\text{B}} = 0.930 \) mol benzene/mol

- \( y_{7\text{T}} = 0.070 \) mol toluene/mol

The column bottoms contain:

- \( x_{8\text{B}} = 0.240 \) mol benzene/mol

- \( x_{8\text{T}} = 0.760 \) mol toluene/mol

The bottom stream is then recycled back to the fresh feed. Hydrogen is fed into the process at \( n_1 = 1710 \) mol H₂/h. This entire process is conducted at a pressure of 760 mmHg.](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2Fe8e4ba9c-f4e2-4406-a528-e4a92bd942c6%2F9d00044c-0db1-4c6d-8a13-c405aa2c43ec%2F3dhgd59_processed.jpeg&w=3840&q=75)

Transcribed Image Text:**Hydrodealkylation of Toluene for Benzene Production**

One of the ways that benzene is produced on a large scale is through the hydrodealkylation of toluene. The chemical reaction involved is:

\[ \text{C}_6\text{H}_5\text{CH}_3 + \text{H}_2 \rightarrow \text{C}_6\text{H}_6 + \text{CH}_4 \]

A stream of toluene is combined with a recycle stream and introduced into a reactor along with a stream of pure hydrogen. The reaction occurs at 550°C. The products then enter a condenser where they are cooled to 43.0°C.

- The vapor stream contains:

- \( y_{\text{CH}_4} = 0.530 \) mol CH₄/mol

This vapor stream exits the process, and a liquid stream, with the following composition, enters a distillation column:

- \( x_{6\text{B}} = 0.740 \) mol benzene/mol

- \( x_{6\text{T}} = 0.260 \) mol toluene/mol

The distillate from the column exits the process at \( n_7 = 781.0 \) mol/h with:

- \( y_{7\text{B}} = 0.930 \) mol benzene/mol

- \( y_{7\text{T}} = 0.070 \) mol toluene/mol

The column bottoms contain:

- \( x_{8\text{B}} = 0.240 \) mol benzene/mol

- \( x_{8\text{T}} = 0.760 \) mol toluene/mol

The bottom stream is then recycled back to the fresh feed. Hydrogen is fed into the process at \( n_1 = 1710 \) mol H₂/h. This entire process is conducted at a pressure of 760 mmHg.

Transcribed Image Text:**Educational Content:**

**Determining Mole Fractions and Flow Rates in a Vapor Stream**

This exercise focuses on calculating the mole fractions of benzene and toluene in a vapor stream, as well as determining the flow rates in a chemical process.

**Parameters:**

- **\( y_{5b} \):** Mole fraction of benzene (b) in the vapor stream leaving the condenser.

- Unit: mol b/mol

- **\( y_{5t} \):** Mole fraction of toluene (t) in the vapor stream leaving the condenser.

- Unit: mol t/mol

- **\( n_2 \):** Flow rate of fresh toluene into the process.

- Unit: mol t/hr

- **\( n_8 \):** Flow rate of the recycle stream.

- Unit: mol/hr

**Exercise:**

1. Calculate \( y_{5b} \) using the given information or a provided formula.

2. Calculate \( y_{5t} \) using the given information or a provided formula.

3. Determine \( n_2 \) which is the input flow rate of fresh toluene.

4. Calculate \( n_8 \) which represents the flow rate of the recycle stream in the process.

Complete the calculations and input your results in the respective boxes for each parameter. This exercise helps in understanding the distribution and flow rates of chemical compounds in industrial processes.

Expert Solution

Step 1

Write the reaction as follows:

Draw the flow diagram according to the given problem as follows:

Step by step

Solved in 6 steps with 1 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The