If a throttling valve is connected to the outlet for one of these tanks, whereby air leaves this valve steadily at 305K with a pressure drop of 50bar, apply an exergy balance across the valve and calculate the exergy change (units: kJ/kg)

If a throttling valve is connected to the outlet for one of these tanks, whereby air leaves this valve steadily at 305K with a pressure drop of 50bar, apply an exergy balance across the valve and calculate the exergy change (units: kJ/kg)

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

If a throttling valve is connected to the outlet for one of these tanks, whereby air leaves this valve steadily at 305K with a pressure drop of 50bar, apply an exergy balance across the valve and calculate the exergy change (units: kJ/kg).

Transcribed Image Text:CAES-Background Info to (Calculated) Questions

A small-scale Compressed Air Energy Storage (CAES) system uses gas tank storage,

with any single tank sized to carry a maximum 2000kg air. The air storage helps

support various fluid power (pneumatics) requirements, but also serves for energy

storage (at 100% charge).

The CAES system sits in a plant room at a geographical location with an environmental

temperature of 300K and ambient pressure of 1 atmosphere (101.325kPa). Due to the

presence of other equipment in the plant room and its built-up nature, is the

immediate surroundings from which tanks are filled are normally a little warmer

compared to the outside ambient air (but same ambient pressure). The plant room

itself is at 310K.The specification for a single tank stipulates it can only be filled with

(dry) air to a maximum (gauge) pressure of 500bar (at typical operating conditions).

When left inside the plant room, the CAES system eventually attains the plant room

temperature.

You may assume:

Steady state conditions apply

Negligible changes in kinetic and potential energy

• Thermal mass of the tank (metal) is negligible

• Air behaves as an ideal gas

●

A gas tank is rigid

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

the pressure dropped by 50 bar and the initial was 500 bar so P2 should be 450 bar. Also, how did u get this ln50500

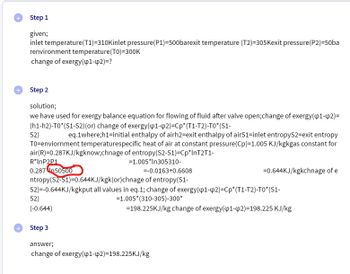

Transcribed Image Text:Step 1

given;

inlet temperature(T1)=310Kinlet pressure(P1)=500barexit temperature (T2)=305Kexit pressure(P2)=50ba

renvironment temperature(TO)=300K

change of exergy(41-42)=?

Step 2

solution;

we have used for exergy balance equation for flowing of fluid after valve open;change of exergy(41-42)=

(h1-h2)-TO*(S1-S2)(or) change of exergy(41-42)=Cp*(T1-T2)-T0*(S1-

eq.1where;h1=initial enthalpy of airh2=exit enthalpy of airS1=inlet entropyS2-exit entropy

TO=enviornment temperaturespecific heat of air at constant pressure(Cp)=1.005 KJ/kgkgas constant for

air(R)=0.287KJ/kgknow;chnage of entropy(S2-S1)=Cp*lnT2T1-

S2)

R*InP2P1

0.287 50500

S2)

(-0.644)

=1.005*In305310-

=-0.0163+0.6608

ntropy(S2-S1)=0.644KJ/kgk(or)chnage of entropy(S1-

S2)=-0.644KJ/kgkput all values in eq.1; change of exergy(41-q2)=Cp* (T1-T2)-T0*(S1-

=1.005* (310-305)-300*

=198.225KJ/kg change of exergy(p1-q2)=198.225 KJ/kg

Step 3

=0.644KJ/kgkchnage of e

answer;

change of exergy(p1-p2)=198.225KJ/kg

Solution

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY