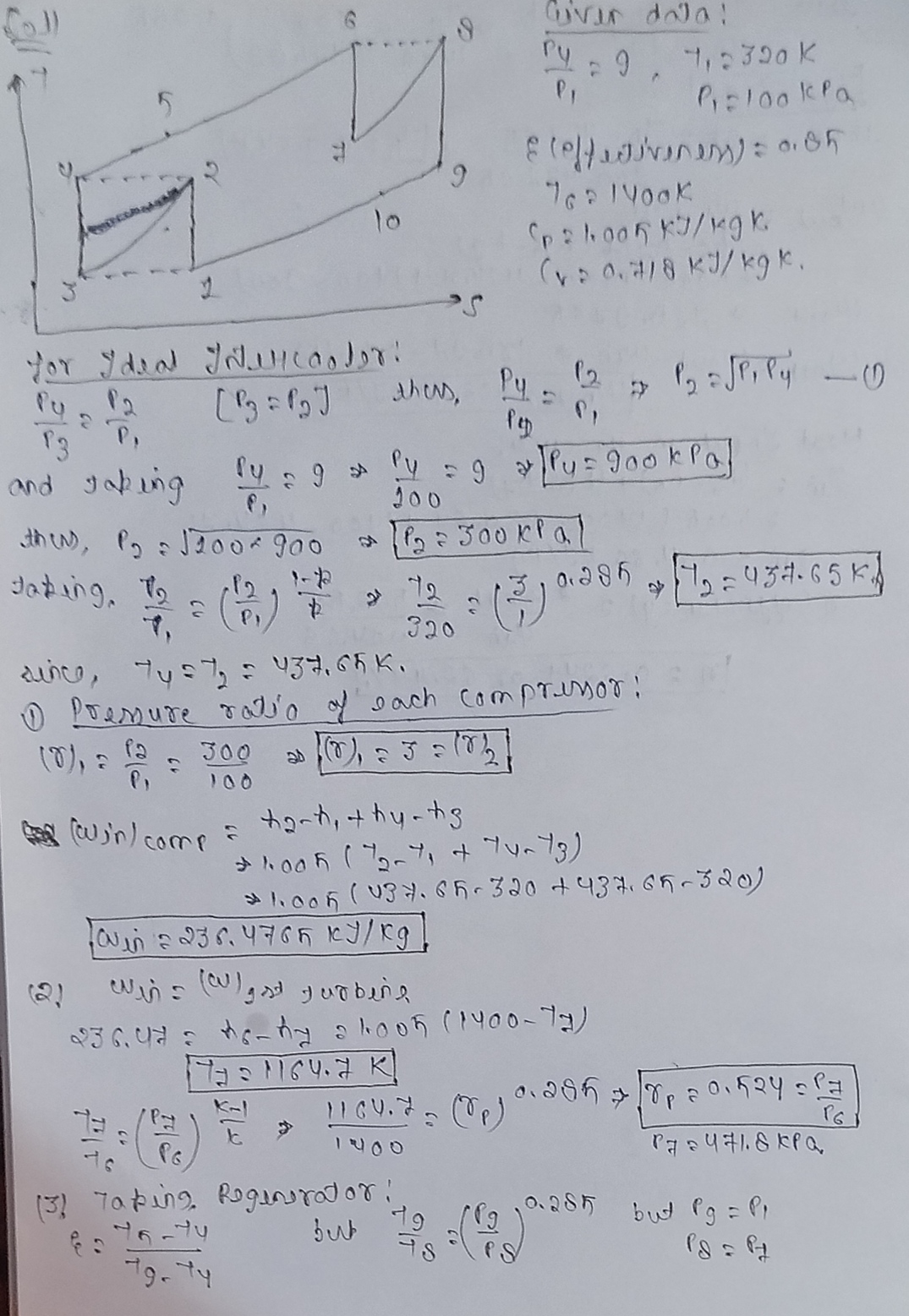

An ideal gas turbine cycle consisting of 2 stages of compression and 2 stages of expansion has an overall pressure ratio of 9. Air enters the compressors at the temperature of 320 K while, being intercooled between the stages. Air enters the first compressor at 100 kPa and the pressure ratio of each of the compressors are selected in a way that minimizes the total power input for the compressors. The high-pressure turbine (First one) drives the compressors and the low-pressure one produces power output. The compressors and both the high-pressure and low-pressure turbines can be assumed ideal. To increase the efficiency of the cycle a regenerator with effectiveness of 85% is used to recover some heat from the exhaust of the second turbine. In this cycle, air with the temperature of 1400 K enters the first turbine. After expansion in the first turbine, air is reheated to the same temperature at the inlet of the first turbine (1400 K). You can consider constant specific heats of c,1.005 kJ/kg.K and c,0.718 kJ/kg.K to analyze this problem and air can be assumed ideal gas. (Hint: Try to use equation of =(2) to relate pressure and temperature in the isentropic processes) and (k: a) Determine the pressure ratio of each of the compressors and total specific work input to the compressors. b) What is the pressure ratio of the high-pressure turbine? (Hint: The work output of the first turbine should be equal to total work input to the compressors.) c) Find the net specific work output of the cycle. d) Determine the thermal efficiency of the cycle. Repere Reheter Comteie chanter Comper Comp Tuti Twie I er

An ideal gas turbine cycle consisting of 2 stages of compression and 2 stages of expansion has an overall pressure ratio of 9. Air enters the compressors at the temperature of 320 K while, being intercooled between the stages. Air enters the first compressor at 100 kPa and the pressure ratio of each of the compressors are selected in a way that minimizes the total power input for the compressors. The high-pressure turbine (First one) drives the compressors and the low-pressure one produces power output. The compressors and both the high-pressure and low-pressure turbines can be assumed ideal. To increase the efficiency of the cycle a regenerator with effectiveness of 85% is used to recover some heat from the exhaust of the second turbine. In this cycle, air with the temperature of 1400 K enters the first turbine. After expansion in the first turbine, air is reheated to the same temperature at the inlet of the first turbine (1400 K). You can consider constant specific heats of c,1.005 kJ/kg.K and c,0.718 kJ/kg.K to analyze this problem and air can be assumed ideal gas. (Hint: Try to use equation of =(2) to relate pressure and temperature in the isentropic processes) and (k: a) Determine the pressure ratio of each of the compressors and total specific work input to the compressors. b) What is the pressure ratio of the high-pressure turbine? (Hint: The work output of the first turbine should be equal to total work input to the compressors.) c) Find the net specific work output of the cycle. d) Determine the thermal efficiency of the cycle. Repere Reheter Comteie chanter Comper Comp Tuti Twie I er

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Transcribed Image Text:An ideal gas turbine cycle consisting of 2 stages of compression and 2 stages of expansion has an

overall pressure ratio of 9. Air enters the compressors at the temperature of 320 K while, being

intercooled between the stages. Air enters the first compressor at 100 kPa and the pressure ratio of each

of the compressors are selected in a way that minimizes the total power input for the compressors. The

high-pressure turbine (First one) drives the compressors and the low-pressure one produces power

output. The compressors and both the high-pressure and low-pressure turbines can be assumed ideal.

To increase the efficiency of the cycle a regenerator with effectiveness of 85% is used to recover some

heat from the exhaust of the second turbine. In this cycle, air with the temperature of 1400 K enters the

first turbine. After expansion in the first turbine, air is reheated to the same temperature at the inlet of

the first turbine (1400 K). You can consider constant specific heats of c,1.005 kJ/kg.K and c,0.718

kJ/kg.K to analyze this problem and air can be assumed ideal gas. (Hint: Try to use equation of

=(2)

to relate pressure and temperature in the isentropic processes) and (k:

a) Determine the pressure ratio of each of the compressors and total specific work input to the

compressors.

b) What is the pressure ratio of the high-pressure turbine? (Hint: The work output of the first turbine

should be equal to total work input to the compressors.)

c) Find the net specific work output of the cycle.

d) Determine the thermal efficiency of the cycle.

Repere

Reheter

Comteie

chanter

Comper

Comp

Tuti

Twie

I er

Expert Solution

Step 1: Given data

Step by step

Solved in 2 steps with 2 images

Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY