7o solid steel shafts are connected to f a disk B. Knowing the modulus of = d the allowable shear stress is 90 M raue T that can be applied to the dis

7o solid steel shafts are connected to f a disk B. Knowing the modulus of = d the allowable shear stress is 90 M raue T that can be applied to the dis

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Transcribed Image Text:**Educational Content: Analysis of Torque in Steel Shafts**

**Problem Statement:**

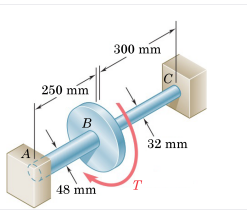

Two solid steel shafts are connected to fixed supports at points A and C, and to a disk at point B. The modulus of rigidity of the steel is given as 75 GPa, and the allowable shear stress is 90 MPa. Determine the maximum torque (T) that can be applied to the disk.

**Diagram Explanation:**

The diagram illustrates a mechanical system with two steel shafts and fixed supports:

1. **Supports and Shafts:**

- The fixed supports are located at points A and C.

- The shaft connected to support A has a diameter of 48 mm and a length of 250 mm.

- The shaft connected to support C has a diameter of 32 mm and a length of 300 mm.

2. **Disk:**

- A disk is attached at point B, which connects both shafts.

3. **Torque:**

- Torque (T) is applied to the disk at point B. The direction of the applied torque is indicated with a red arrow.

**Objective:**

To calculate the maximum allowable torque (T) that can be applied at disk B without exceeding the allowable shear stress of 90 MPa.

**Material Properties:**

- Modulus of rigidity, G = 75 GPa

- Allowable shear stress = 90 MPa

**Analysis Approach:**

1. Assess the torsional deformation and stresses introduced in the shafts due to the applied torque.

2. Utilize relationships between torque, shear stress, and the modulus of rigidity to solve for the maximum torque.

**Conclusion:**

This problem requires understanding the mechanical properties and behavior of materials under torsion. Calculating the appropriate maximum torque ensures structural integrity and safety in mechanical systems.

Expert Solution

Step 1

Step by step

Solved in 2 steps with 1 images

Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY