Interpretation:

The shaft design using the appropriate material for given condition should be determined.

Concept introduction:

Endurance strength is the value of maxium reveresed bending stress that a material can withstand without failure for finite number of cycle.

The following condition are specified based on number of cycle, If number of cycles are more than

Endurance Ratio:

It is defined as the ratio of endurance limit to tensile strength, the relationship is given below:

It helps to estimate the properties of fatigue using tensile test. The value of endurance limit for metallic material is 0.3 to 0.4.

Relationship for endurance limit is shown below:

Where,

F is the applied load in pounds.

L is the length I inch.

D is the diameter in inch.

Answer to Problem 7.66DP

Magnesium-Manganese alloy is best suitable material for shaft designing based on the value of fatigue strength.

Explanation of Solution

Given Information:

The value of load is

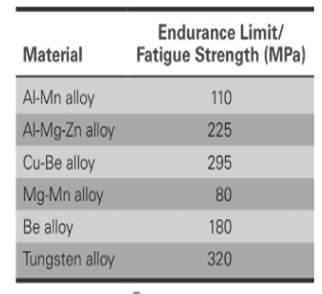

The material used along with the values of fatigue strength is shown in table below:

The required values are shown in table,

The relationship for Endurance limit is,

Considering the case for Aluminum manganese alloy,

The amount of load applied is

The value of fatigue strength for aluminum- manganese alloy is

Value of fatigue strength in psi is

Assuming the value of length as

Substituting the values in the above formula,

Thus, the required value of diameter for shaft designing is

Considering the case for Aluminum magnesium and zinc alloy,

The amount of load applied is

The value of fatigue strength for aluminum- manganese alloy is

Value of fatigue strength in psi is

Assuming the value of length as

Substituting the values in the above formula,

Thus, the required value of diameter for shaft designing is

Considering the case for Aluminum- Beryllium alloy,

The amount of load applied is

The value of fatigue strength for aluminum- manganese alloy is

Value of fatigue strength in psi is

Assuming the value of length as

Substituting the values in the above formula,

Thus, the required value of diameter for shaft designing is

Considering the case for Magnesium- Manganese alloy,

The amount of load applied is

The value of fatigue strength for aluminum- manganese alloy is

Value of fatigue strength in psi is

Assuming the value of length as

Substituting the values in the above formula,

Thus, the required value of diameter for shaft designing is

Considering the case for Beryllium alloy,

The amount of load applied is

The value of fatigue strength for aluminum- manganese alloy is

Value of fatigue strength in psi is

Assuming the value of length as

Substituting the values in the above formula,

Thus, the required value of diameter for shaft designing is

Considering the case for Tungsten alloy,

The amount of load applied is

The value of fatigue strength for aluminum- manganese alloy is

Value of fatigue strength in psi is

Assuming the value of length as

Substituting the values in the above formula,

Thus, the required value of diameter for shaft designing is

The required values are shown table,

| Alloys | Fatigue Strength (MPa) | Calculated diameter in inch |

| Al-Mg | 110 | 7.8229 |

| Al-Mg-Zn | 225 | 6.162 |

| Cu-Be | 295 | 5.630 |

| Mg-Mn | 80 | 8.69 |

| Be | 180 | 6.638 |

| W | 320 | 5.480 |

Designing of shaft is based on the stress level. On comparing, the values of fatigue strength the alloys of magnesium and manganese gives the lower value of fatigue strength as compared to other.

Thus, based on the fatigue strength value, Mg-Mn is suitable for designing of the shaft.

The best suitable material for shaft designing based on the value of fatigue strength is Magnesium-Manganese alloy.

Want to see more full solutions like this?

Chapter 7 Solutions

Essentials Of Materials Science And Engineering

- What are the two errors in my pseudocode?Module getAverage(Integer value1, Integer value2, Integer value3) Declare Integer average average = value1 + value2 + value3 / 3 Display average End Modulearrow_forwardWhere did I make an error in my pseudocode module???Code:Module main() Call raiseToPower(2, 1.5) End main Module raiseToPower(Real value, Integer power) Declare Real result Set result = value ^ power Display result End raiseToPowerarrow_forwardWhy does my pseudocode not perform what I asked? Don't know whats wrong with it.// This program asks the user to enter a value // between 1 and 10 and validates the input. Declare Integer value // Get a value from the user. Display "Enter a value between 1 and 10." Input value // Make sure the value is between 1 and 10. While value < 1 AND value > 10 Display "ERROR: The value must be between 1 and 10." Display "Enter a value between 1 and 10." Input value End Whilearrow_forward

- What's wrong with my pseudocode? // The calcDiscountPrice function accepts an item’s price and // the discount percentage as arguments. It uses those // values to calculate and return the discounted price. Function Real calcDiscountPrice(Real price, Real percentage) // Calculate the discount. Declare Real discount = price * percentage // Subtract the discount from the price. Declare Real discountPrice = price – discount // Return the discount price. Return discount End Functionarrow_forwardNeed help converting my pseudocode to python, AND have a flowchart showing everything!The code: Function getScore() // Prompt the user to enter a test score Display "Enter a test score as a percentage (0-100): " Input score // Return the score entered by the user Return scoreEnd Function Function getGPAPoint(Integer score) // Determine GPA point based on the score If score >= 90 Then Return 4.0 Else If score >= 80 Then Return 3.0 Else If score >= 70 Then Return 2.0 Else If score >= 60 Then Return 1.0 Else Return 0.0 End IfEnd Function Function getAverage() // Initialize variables to store the sum of scores and GPA points totalScore = 0 totalGPA = 0.0 // Loop to collect 5 test scores For i = 1 to 5 Do score = getScore() // Call getScore function to get a test score totalScore = totalScore + score // Add score to totalScore gpaPoint = getGPAPoint(score) // Convert…arrow_forwardWhere did I make an error in my pseudocode module???Code:Module main() Call raiseToPower(2, 1.5) End main Module raiseToPower(Real value, Integer power) Declare Real result Set result = value ^ power Display result End raiseToPowerarrow_forward

- I need help writing pseudocode for calculating class score average by putting in 5 test scores, and showing the average from all 5 inputs and the GPA score.Starting with 3 functions outside of a main module. The functions are getScore(), getGPAPoint(Integer score), and getAverage(). Function getscore is an input for a grade as a class percentage. Function getGPAPoint will calculate the score into a GPA point and return as a float (values of 90-100 as 4.0, 80-89 as 3.0, 70-79 as 2.0, 60-69 as 1.0, and anything below 60 as 0.) Function averageGPA will finally make a call to both previous functions when the user inputs numbers 5 times that then calculates the average (add up all the scores, divide by 5) and the average grade alongside displaying the average GPA. End result is a main module that makes a proper call to the averageGPA function and display its results. Need help with this!arrow_forwardPlease original work Why is integration between data collection and business analysis so important to success in an organization that uses business analytics? How can a company that is just starting to use business analytics set up its program for success right from the beginning? Please cite in text references and add weblinksarrow_forwardHow to make a 1 bit adder with CLA?arrow_forward

- (Read Image) (Answer: ω = 1.10 rad/sec CW)arrow_forwardI need help writing pseudocode for this function. The following pseudocode statement calls a function named half, which returns a value that is half that of the argument. (Assume both the result and number variables are Real.) Set result = half(number)arrow_forwardNeed help converting my pseudocode to python, AND have a flowchart showing everything!The code:Main Module Call InputModuleEnd Main Module Module InputModule // This module gets input from the user Declare Principal, AnnualRate, Years as Float Output "Enter the Principal amount (P): " Input Principal Output "Enter the Annual Interest Rate (in percentage, e.g., 5 for 5%): " Input AnnualRate Output "Enter the number of Years to repay the loan: " Input Years Call DisplayPayment(Principal, AnnualRate, Years)End Module Module DisplayPayment(Principal, AnnualRate, Years) // This module calculates and displays the monthly payment Declare R, N as Float Declare MonthlyPayment as Float Declare PowerFactor as Float // second local variable // Calculate monthly interest rate R and number of months N Set R = (AnnualRate / 100) / 12 Set N = Years * 12 // Calculate PowerFactor = (1 + R)^N Set PowerFactor = (1 + R) ^ N // Calculate…arrow_forward

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY