Concept explainers

(a)

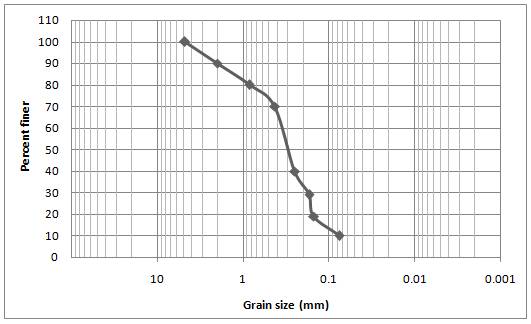

To plot: Grain size distribution curve.

Answer to Problem 18P

Explanation of Solution

Given information:

| Sieve No. | Sieve No. | Percent finer |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| Pan | Pan | -- |

Concept used:

Plot the grain size distribution curve between the sieve number (mm) and the percent finer. The sieve number (mm) is plotted in x -axis and percent finer in y -axis.

Calculation:

Conclusion:

The grain distribution curve is plotted.

(b)

The values of

Answer to Problem 18P

Explanation of Solution

Given information:

| Sieve No. | Sieve No. | Percent finer |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| Pan | Pan | -- |

Concept used:

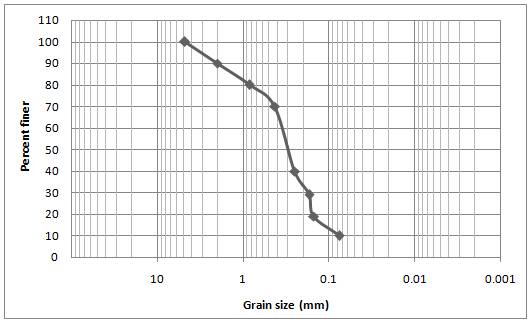

Plot the grain size distribution curve between the sieve number (mm) and the percent finer. The sieve number (mm) is plotted in x -axis and percent finer in y -axis. Then the corresponding values of

Calculation:

Conclusion:

The values of

(c)

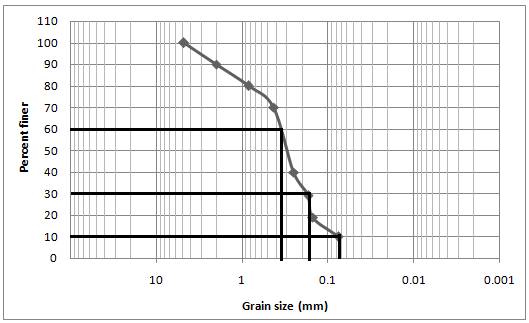

The value of uniformity coefficient

Answer to Problem 18P

Explanation of Solution

Given information:

| Sieve No. | Sieve No. | Percent finer |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| Pan | Pan | -- |

Concept used:

Calculation:

Conclusion:

The value of coefficient of uniformityis

(d)

The value of coefficient of gradation

Answer to Problem 18P

Explanation of Solution

Given information:

| Sieve No. | Sieve No. | Percent finer |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| Pan | Pan | -- |

Concept used:

Calculation:

Conclusion:

The value of coefficient of uniformity is

Want to see more full solutions like this?

- Please write me Background Reviews;arrow_forwardQ1/ The specific gravity of the soil is 1.41 percentage of water content by weight at field capacity and wilting point are 15% and 7% respectively calculate the equivalent moisture content as equivalent depth for 1.2m root zone : 1. at permanent wilting point 2. at field capacity 3. for ready available waterarrow_forwardKindy explain the pie chart percentage and give some related study and references about Value of travel time connected to the pie chartarrow_forward

- Consider the specifications for an asphaltic concrete mixture and the results of a sieve analysis below. Coarse aggregates: Fine aggregates: Filler: 60% 35% 5% Percent of Weight of Aggregate or Filler Passing Sieve Designation Retained on Sieve Designation Coarse Aggregate Fine Aggregate Mineral Filler 3/4 in. (19 mm) 1/2 in. 6 1/2 in. (12.5 mm) 3/8 in. 15 3/8 in. (9.5 mm) No. 4 50 - No. 4 (4.75 mm) No. 10 20 1 No. 10 (2 mm) No. 40 (0.425 mm) No. 40 9 35 - No. 80 31 40 No. 80 (0.180 mm) No. 200 (0.075 mm) Total No. 200 - 33 - - 25 35 100 100 100 Determine the proportion of different aggregates to obtain the required gradation. Percent of Total Weight of Mixture Passing Sieve Designation Retained on Sieve Designation Coarse Aggregate Fine Aggregate 3/4 in. (19 mm) 1/2 in. (12.5 mm) 3/8 in. (9.5 mm) 1/2 in. 3/8 in. No. 4 No. 4 (4.75 mm) No. 10 No. 10 (2 mm) No. 40 No. 40 (0.425 mm) No. 80 No. 80 (0.180 mm) No. 200 No. 200 (0.075 mm) Total Need Help? Read It Mineral Filler Total 100arrow_forwardResults obtained from laboratory tests on a sample of RC-250 asphalt cement are given. Determine whether the properties of this material meet the Asphalt Institute specifications for this type of material; if not, note the differences. (For each specification, enter the minimum acceptab value in the same units as used in the test results.) • Kinematic viscosity at 140°F (60°C) = 230 centistokes • Flash point (Tagliabue open cup) = 89°F • Distillation test where distillate percent by volume of total distillate to 680°F (360ºC) • To 437°F (225°C) = 27% • To 500°F (260°C) = 69% • To 600°F (316°C) = 72% • Residue from distillation to 680°F (360°C) by volume percentage of sample by difference • Tests on Residue from Distillation: • Ductility at 77°F (25°C) = 92 cm • Absolute viscosity at 140°F (60°C) = 620 poises ⚫ Solubility = 90% Property Kinematic Viscosity = 74% Specification Test Results Were Specifications Met? centistokes 230 centistokes ---Select--- ✓ Flash Point °F 89°F…arrow_forwardProblem 2 Two machines produce rivets for a factory job. The number of sub-standard rivets per hour by the two machines are random variables, denoted by X1 and X2. The bivariate PMF of X1 and X2, Px,x,(x1,x2), is given in the table below. X2=0 X2=1 X2=2 X2=3 X₁-0 0.07 0.05 0.02 0.01 X₁ =1 0.05 0.16 0.12 0.02 X₁ =2 0.02 0.12 0.17 0.05 X₁ =3 0.01 0.01 0.05 0.07arrow_forward

- please helparrow_forwardAS Q1/ The specific gravity of the soil is 1.41 percentage of water content by weight at field capacity and wilting point are 15% and 7% respectively calculate the equivalent moisture content as equivalent depth for 1.2m root zone : 1. at permanent wilting point 2. at field capacity 3. for ready available waterarrow_forwardQuestion 6 The following figure shows peak-hour volumes for an intersection. Using Webster's method, determine a suitable signal timing for the intersection using the four-phase system shown below. Use an amber interval of 3 seconds and the saturation flow given in the table. O 100 O Phase Lime Group Saturation Flow A e 1615-> 370 3700 B 1615 1615 3700 1615 3700arrow_forward

Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Principles of Geotechnical Engineering (MindTap C...Civil EngineeringISBN:9781305970939Author:Braja M. Das, Khaled SobhanPublisher:Cengage Learning

Principles of Geotechnical Engineering (MindTap C...Civil EngineeringISBN:9781305970939Author:Braja M. Das, Khaled SobhanPublisher:Cengage Learning Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781305081550Author:Braja M. DasPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781305081550Author:Braja M. DasPublisher:Cengage Learning