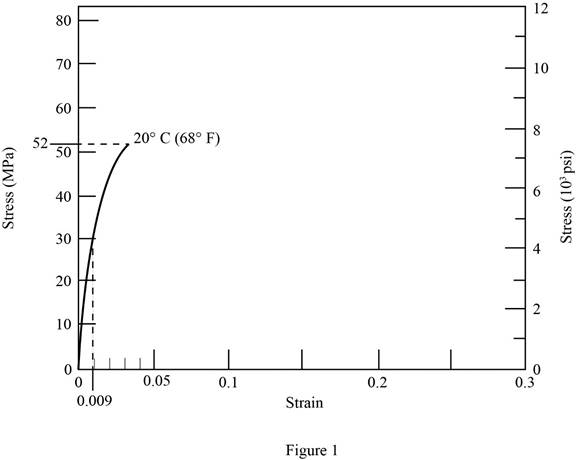

The elastic modulus and tensile strength of the poly (methyl methacrylate) from the stress strain data given in Figure 15.3 at room temperature

Answer to Problem 1QAP

The calculated elastic modulus of the poly (methyl methacrylate) is slightly greater than the maximum value of elastic modulus given in the Table 15.2 that is

The tensile strength (stress) found from the Figure 15.3 (

Explanation of Solution

Write the relation between elastic modulus, tensile strength and strain.

Here,

Conclusion:

Refer to Figure 15.3. “The influence of temperature on the stress strain characteristics of poly (methyl methacrylate)”.

The stress and strain corresponding to the temperature curve of

From Figure 1.

Let, the initial stress and strain corresponding to the temperature curve of

Let, the final stress and strain corresponding to the temperature curve of

Calculate the elastic modulus.

Substitute

Thus, the elastic modulus of poly (methyl methacrylate) is

Refer to Table 15.2, “Room-Temperature

The elastic modulus corresponding to poly (methyl methacrylate) is

Hence, the calculated elastic modulus of the poly (methyl methacrylate) is slightly greater than the maximum value of elastic modulus given in the Table 15.2 that is

From Figure 1.

The tensile strength (stress) at the end of the curve corresponding to the temperature curve of

Refer to Table 15.2, “Room-Temperature mechanical characteristics of some of the more common polymers”.

The tensile strength (stress) corresponding to poly (methyl methacrylate) is

Hence, the tensile strength (stress) found from the Figure 15.3 (

Want to see more full solutions like this?

Chapter 15 Solutions

MAT.SCIENCE+ENGIN.(PERUSALL ACCESS)

- Note that the solution should be handwritten showing how you managed to break the cipher. You can Scan and upload your solution. Hint: The Cipher text given below is encrypted using reciprocal substitution. Use Frequency Analysis to break this Cipher. MOBUEWO LI QOUOYNYVA PZYF BOPPOQ IEC GQO EVO ES PZO SOM UZEFOV PE NYFYP CF GP PZO SYSPZ VOJP WEVPZ GVK PGDO TGQP ES PZO OBOUPYEV TQEUOFF MO ZETO PZGP IEC ZGNO PZO TEFFYLYBYPI PE AYNO CF PZO TBOGFCQO ES IECQ UEWTGVI GVK PZGP IEC GUUOTP PZO ZEVECQ GF MOBB GF PZO QOFTEVFYLYBYPI ES PZYF GFFYAVWOVP PZYF IOGQ PZO WOOPYVA MYBB PGDO TBGUO GP DOVFYVAPEV VYVO PGDO PZO LCF PZQOO ZCVKQOK PMOBNO FONOV FPGPYEVF SQEW PZO UOVPQGB DOOT PZO GKKQOFF GF MOBB GF PZO KGI G FOUQOP LOFP QOAGQKFarrow_forward4. A battery operated sensor transmits to a receiver that is plugged in to a power outlet. The device is continuously operated. The battery is a 3.6 V coin-cell battery with a 245mAHr capacity. The application requires a bit rate of 36 Mbps and an error rate of less than 10^-3. The channel has a center frequency of 2.4 GHz, a bandwidth of 10 MHz and a noise power spectral density of 10^-14 W/Hz. The maximum distance is 36 meters and the losses in the channel attenuates the signal by 0.25 dB/meter. Your company has two families of chips that you can use. An M-ary ASK and an M-ary QAM chip. The have very different power requirements as shown in the table below. The total current for the system is the current required to achieve the desired Eb/No PLUS the current identified below: Hokies PSK Chip Set Operating Current NOT Including the required Eb/No for the application Hokies QAM Chip Set Operating Current NOT Including the required Eb/No for the application Chip ID M-ary Voltage (volts)…arrow_forward8. A prestressed concrete beam is subjected to the following stress distributions: Pi is the initial prestressing force, Pe is the effective prestressing force, M, is the bending moment due to self- weight, Ma and M, are the dead load and live load bending moment, respectively. The concrete has the following properties: fr = 6000 psi and fri = 4200 psi +250 -85 -2500 +550 Pe+ Mo+Ma+Mi P alone P₁+ Mo -2450 -3500 Stress at midspan +210 +250 P, alone Pe alone -2500 -3500 Stress at ends Using Table 22.1, evaluate whether the stresses at the center of the span and the end of the span comply with the permissible stress limits. The beam is classified as U-class. Provide justifications for each condition listed in the table. Note: Calculated stresses are to be taken from the above diagram, and permissible stresses are to be calculated using Table 22.1. Compressive stresses immediately after transfer Tensile stresses immediately after transfer Compressive stresses under sustained and total…arrow_forward

- Using the 802.11a specifications given below, in Matlab (or similar tool) create the time domain signal for one OFDM symbol using QPSK modulation. See attached plot for the QPSK constellation. Your results should include the power measure in the time and frequency domain and comment on those results. BW 802.11a OFDM PHY Parameters 20 MHZ OBW Subcarrer Spacing Information Rate Modulation Coding Rate Total Subcarriers Data Subcarriers Pilot Subcarriers DC Subcarrier 16.6 MHZ 312.5 Khz (20MHz/64 Pt FFT) 6/9/12/18/24/36/48/54 Mbits/s BPSK, QPSK, 16QAM, 64QAM 1/2, 2/3, 3/4 52 (Freq Index -26 to +26) 48 4 (-21, -7, +7, +21) *Always BPSK Null (0 subcarrier) 52 subarriers -7 (48 Data, 4 Pilot (BPSK), 1 Null) -26 -21 0 7 21 +26 14 One Subcarrier 1 OFDM symbol 1 OFDM Burst -OBW 16.6 MHz BW 20 MHZ 1 constellation point = 52 subcarriers = one or more OFDM symbols 802.11a OFDM Physical Parameters Show signal at this point x bits do Serial Data d₁ S₁ Serial-to- Input Signal Parallel Converter IFFT…arrow_forwardFind Vb and Va using Mesh analysisarrow_forward1. The communication channel bandwidth is 25 MHz centered at 1GHz and has a noise power spectral density of 10^-9 W/Hz. The channel loss between the transmitter and receiver is 25dB. The application requires a bit rate of 200Mbps and BER of less than 10^-4. Excluding Mary FSK, Determine the minimum transmit power required.arrow_forward

- 2. An existing system uses noncoherent BASK. The application requires a BER of <10^-5. The current transmit power is 25 Watts. If the system changes to a coherent BPSK modulation scheme, what is the new transmit power required to deliver the same BER?arrow_forward10. A short column is subjected to an eccentric loading. The axial load P = 1000 kips and the eccentricity e = 12 in. The material strengths are fy = 60 ksi and f = 6000 psi. The Young's modulus of steel is 29000 ksi. (a) Fill in the blanks in the interaction diagram shown below. (2pts each, 10pt total) Po Pn (1) failure range H 3" 30" Ast 6 No. 10 bars = P 22" I e H 3" (4) e = e small Load path for given e Radial lines show constant (2) eb (3) e large failure range Mn (5) e= Mo (b) Compute the balanced failure point, i.e., P and Mb.arrow_forward3. You are to design a 9-volt battery operated communication system that must last 3 years without replacing batteries. The communication channel bandwidth is 100 KHz centered at 5.8 GHz. The application requires a BER of <10^-5 and a data rate of 1 Mbps. The channel can be modeled as AWGN with a noise power spectral density of 10^-8 W/Hz. ((a) What modulation scheme would you use? B) what is the required capacity of the batteries? and (c) is the battery commercially available?arrow_forward

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY