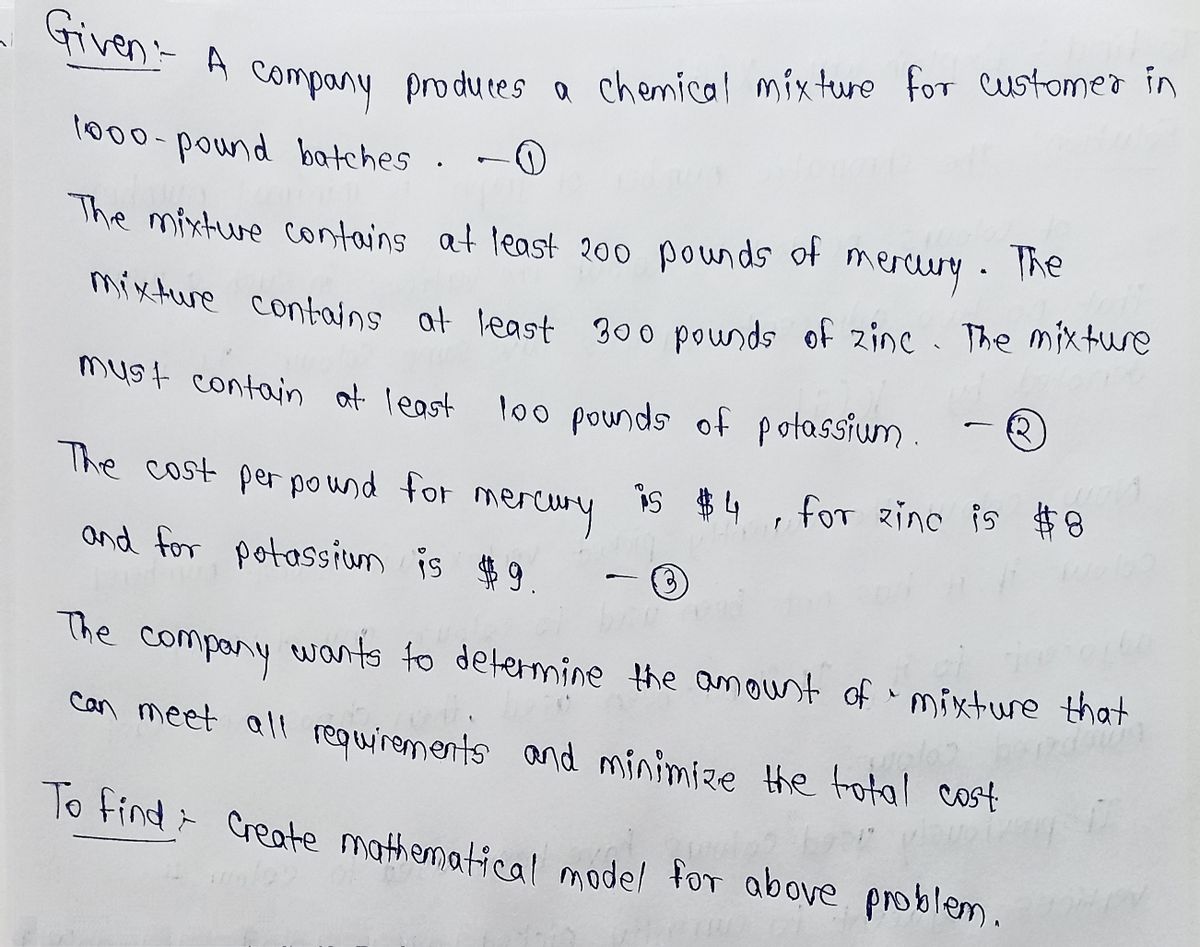

Let's create a mathematical model for the following problem: A chemical company produces a chemical mixture for a customer in 1,000-pound batches. The mixture contains three components: mercury, zinc, and potassium. The mixture must meet specific formula specifications provided by the customer. The company wants to determine the amount of mixture that can meet all requirements and minimize the total cost. The customer provides formula specifications for each batch of the mixture as follows: The mixture must contain at least 200 pounds of mercury. The mixture must contain at least 300 pounds of zinc. The mixture must contain at least 100 pounds of potassium. The cost per pound for mercury is $4, for zinc is $8, and for potassium is $9.

Let's create a mathematical model for the following problem: A chemical company produces a chemical mixture for a customer in 1,000-pound batches. The mixture contains three components: mercury, zinc, and potassium. The mixture must meet specific formula specifications provided by the customer. The company wants to determine the amount of mixture that can meet all requirements and minimize the total cost. The customer provides formula specifications for each batch of the mixture as follows: The mixture must contain at least 200 pounds of mercury. The mixture must contain at least 300 pounds of zinc. The mixture must contain at least 100 pounds of potassium. The cost per pound for mercury is $4, for zinc is $8, and for potassium is $9.

Advanced Engineering Mathematics

10th Edition

ISBN:9780470458365

Author:Erwin Kreyszig

Publisher:Erwin Kreyszig

Chapter2: Second-order Linear Odes

Section: Chapter Questions

Problem 1RQ

Related questions

Question

100%

Let's create a mathematical model for the following problem:

A chemical company produces a chemical mixture for a customer in 1,000-pound batches. The mixture contains three components: mercury, zinc, and potassium. The mixture must meet specific formula specifications provided by the customer. The company wants to determine the amount of mixture that can meet all requirements and minimize the total cost.

The customer provides formula specifications for each batch of the mixture as follows:

The mixture must contain at least 200 pounds of mercury.

The mixture must contain at least 300 pounds of zinc.

The mixture must contain at least 100 pounds of potassium.

The cost per pound for mercury is $4, for zinc is $8, and for potassium is $9.

Expert Solution

Step 1: Introduction to given details

Step by step

Solved in 3 steps with 3 images

Recommended textbooks for you

Advanced Engineering Mathematics

Advanced Math

ISBN:

9780470458365

Author:

Erwin Kreyszig

Publisher:

Wiley, John & Sons, Incorporated

Numerical Methods for Engineers

Advanced Math

ISBN:

9780073397924

Author:

Steven C. Chapra Dr., Raymond P. Canale

Publisher:

McGraw-Hill Education

Introductory Mathematics for Engineering Applicat…

Advanced Math

ISBN:

9781118141809

Author:

Nathan Klingbeil

Publisher:

WILEY

Advanced Engineering Mathematics

Advanced Math

ISBN:

9780470458365

Author:

Erwin Kreyszig

Publisher:

Wiley, John & Sons, Incorporated

Numerical Methods for Engineers

Advanced Math

ISBN:

9780073397924

Author:

Steven C. Chapra Dr., Raymond P. Canale

Publisher:

McGraw-Hill Education

Introductory Mathematics for Engineering Applicat…

Advanced Math

ISBN:

9781118141809

Author:

Nathan Klingbeil

Publisher:

WILEY

Mathematics For Machine Technology

Advanced Math

ISBN:

9781337798310

Author:

Peterson, John.

Publisher:

Cengage Learning,