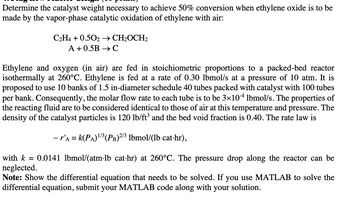

Determine the catalyst weight necessary to achieve 50% conversion when ethylene oxide is to be made by the vapor-phase catalytic oxidation of ethylene with air: C2H4 +0.502 → CH₂OCH2 A +0.5B → C Ethylene and oxygen (in air) are fed in stoichiometric proportions to a packed-bed reactor isothermally at 260°C. Ethylene is fed at a rate of 0.30 lbmol/s at a pressure of 10 atm. It is proposed to use 10 banks of 1.5 in-diameter schedule 40 tubes packed with catalyst with 100 tubes per bank. Consequently, the molar flow rate to each tube is to be 3×104 lbmol/s. The properties of the reacting fluid are to be considered identical to those of air at this temperature and pressure. The density of the catalyst particles is 120 lb/ft³ and the bed void fraction is 0.40. The rate law is - r'a = k(PA)¹/³ (PB) 2/3 lbmol/(lb cat-hr), 0.0141 lbmol/(atm·lb cat·hr) at 260°C. The pressure drop along the reactor can be with k = neglected. Note: Show the differential equation that needs to be solved. If you use MATLAB to solve the differential equation, submit your MATLAB code along with your solution.

Determine the catalyst weight necessary to achieve 50% conversion when ethylene oxide is to be made by the vapor-phase catalytic oxidation of ethylene with air: C2H4 +0.502 → CH₂OCH2 A +0.5B → C Ethylene and oxygen (in air) are fed in stoichiometric proportions to a packed-bed reactor isothermally at 260°C. Ethylene is fed at a rate of 0.30 lbmol/s at a pressure of 10 atm. It is proposed to use 10 banks of 1.5 in-diameter schedule 40 tubes packed with catalyst with 100 tubes per bank. Consequently, the molar flow rate to each tube is to be 3×104 lbmol/s. The properties of the reacting fluid are to be considered identical to those of air at this temperature and pressure. The density of the catalyst particles is 120 lb/ft³ and the bed void fraction is 0.40. The rate law is - r'a = k(PA)¹/³ (PB) 2/3 lbmol/(lb cat-hr), 0.0141 lbmol/(atm·lb cat·hr) at 260°C. The pressure drop along the reactor can be with k = neglected. Note: Show the differential equation that needs to be solved. If you use MATLAB to solve the differential equation, submit your MATLAB code along with your solution.

Oh no! Our experts couldn't answer your question.

Don't worry! We won't leave you hanging. Plus, we're giving you back one question for the inconvenience.

Submit your question and receive a step-by-step explanation from our experts in as fast as 30 minutes.

You have no more questions left.

Message from our expert:

Your MATLAB question does not match the subject you selected. Please ask a question in one of the 30+ subjects available. We've credited a question to your account.

Your Question:

Transcribed Image Text:Determine the catalyst weight necessary to achieve 50% conversion when ethylene oxide is to be

made by the vapor-phase catalytic oxidation of ethylene with air:

C2H4 +0.502 → CH₂OCH2

A +0.5B → C

Ethylene and oxygen (in air) are fed in stoichiometric proportions to a packed-bed reactor

isothermally at 260°C. Ethylene is fed at a rate of 0.30 lbmol/s at a pressure of 10 atm. It is

proposed to use 10 banks of 1.5 in-diameter schedule 40 tubes packed with catalyst with 100 tubes

per bank. Consequently, the molar flow rate to each tube is to be 3×104 lbmol/s. The properties of

the reacting fluid are to be considered identical to those of air at this temperature and pressure. The

density of the catalyst particles is 120 lb/ft³ and the bed void fraction is 0.40. The rate law is

- r'a = k(PA)¹/³ (PB) 2/3 lbmol/(lb cat-hr),

0.0141 lbmol/(atm·lb cat·hr) at 260°C. The pressure drop along the reactor can be

with k =

neglected.

Note: Show the differential equation that needs to be solved. If you use MATLAB to solve the

differential equation, submit your MATLAB code along with your solution.

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The