Blending Problems: This is another large class of problems in which linear programming is applied heavily. Blending is concemed with mixing different materials called the constituents of the mixture (these may be chemicals, gasoline, fuels, solids, colors, foods, etc.) so that the mixture conforms to specifications on several properties or characteristics. To model a blending problem as an LP, the linearity assumptions must hold. This implies that the value for a characteristic for the constituents in the mixtures are the weighted average of the values of that characteristic for the constituents in the mixture; the weights being the proportions of the constituents. As an example, consider a mixture consisting of 4 barrels of fuel 1 and 6 barrels of fuel 2, and suppose the characteristic of interest is the octane rating (Oc.R). If linearity assumptions hold, the Oc.R of the mixture must be equal to (4 times the Oc.R of fuel 1 + 6 times the Oc.R of fuel 2)/(4 +6). These linearity assumptions hold to a reasonable degree of precision for many important characteristics of blends of gasolines, of crude oils, of paints, of foods, etc. That's why linear programming is used extensively in optimizing gasoline blending, in the manufacture of paints, cattle feeds, beverages, etc. The decision variables in a blending problem are usually either the quantities or the proportions of the constituents. Problem: Three liquid mixtures are to be designed as provided in the table below to contain a special chemical called "Optim" Availability [gallons] 800 Cost ($/gallon 20 Optim [%] 45 35 65 30 Material 1000 700 1500 15 30 25 Minimum Optim (%)Optim [%] 25 30 40 Required Amount Igallons] 600 1200 Maximum Selling Price ($/gallon) 70 Mixture 45 50 65 105 140 Y 900 Formulate an LP model to determine the production plan that maximizes profit. 1234

Blending Problems: This is another large class of problems in which linear programming is applied heavily. Blending is concemed with mixing different materials called the constituents of the mixture (these may be chemicals, gasoline, fuels, solids, colors, foods, etc.) so that the mixture conforms to specifications on several properties or characteristics. To model a blending problem as an LP, the linearity assumptions must hold. This implies that the value for a characteristic for the constituents in the mixtures are the weighted average of the values of that characteristic for the constituents in the mixture; the weights being the proportions of the constituents. As an example, consider a mixture consisting of 4 barrels of fuel 1 and 6 barrels of fuel 2, and suppose the characteristic of interest is the octane rating (Oc.R). If linearity assumptions hold, the Oc.R of the mixture must be equal to (4 times the Oc.R of fuel 1 + 6 times the Oc.R of fuel 2)/(4 +6). These linearity assumptions hold to a reasonable degree of precision for many important characteristics of blends of gasolines, of crude oils, of paints, of foods, etc. That's why linear programming is used extensively in optimizing gasoline blending, in the manufacture of paints, cattle feeds, beverages, etc. The decision variables in a blending problem are usually either the quantities or the proportions of the constituents. Problem: Three liquid mixtures are to be designed as provided in the table below to contain a special chemical called "Optim" Availability [gallons] 800 Cost ($/gallon 20 Optim [%] 45 35 65 30 Material 1000 700 1500 15 30 25 Minimum Optim (%)Optim [%] 25 30 40 Required Amount Igallons] 600 1200 Maximum Selling Price ($/gallon) 70 Mixture 45 50 65 105 140 Y 900 Formulate an LP model to determine the production plan that maximizes profit. 1234

Advanced Engineering Mathematics

10th Edition

ISBN:9780470458365

Author:Erwin Kreyszig

Publisher:Erwin Kreyszig

Chapter2: Second-order Linear Odes

Section: Chapter Questions

Problem 1RQ

Related questions

Question

100%

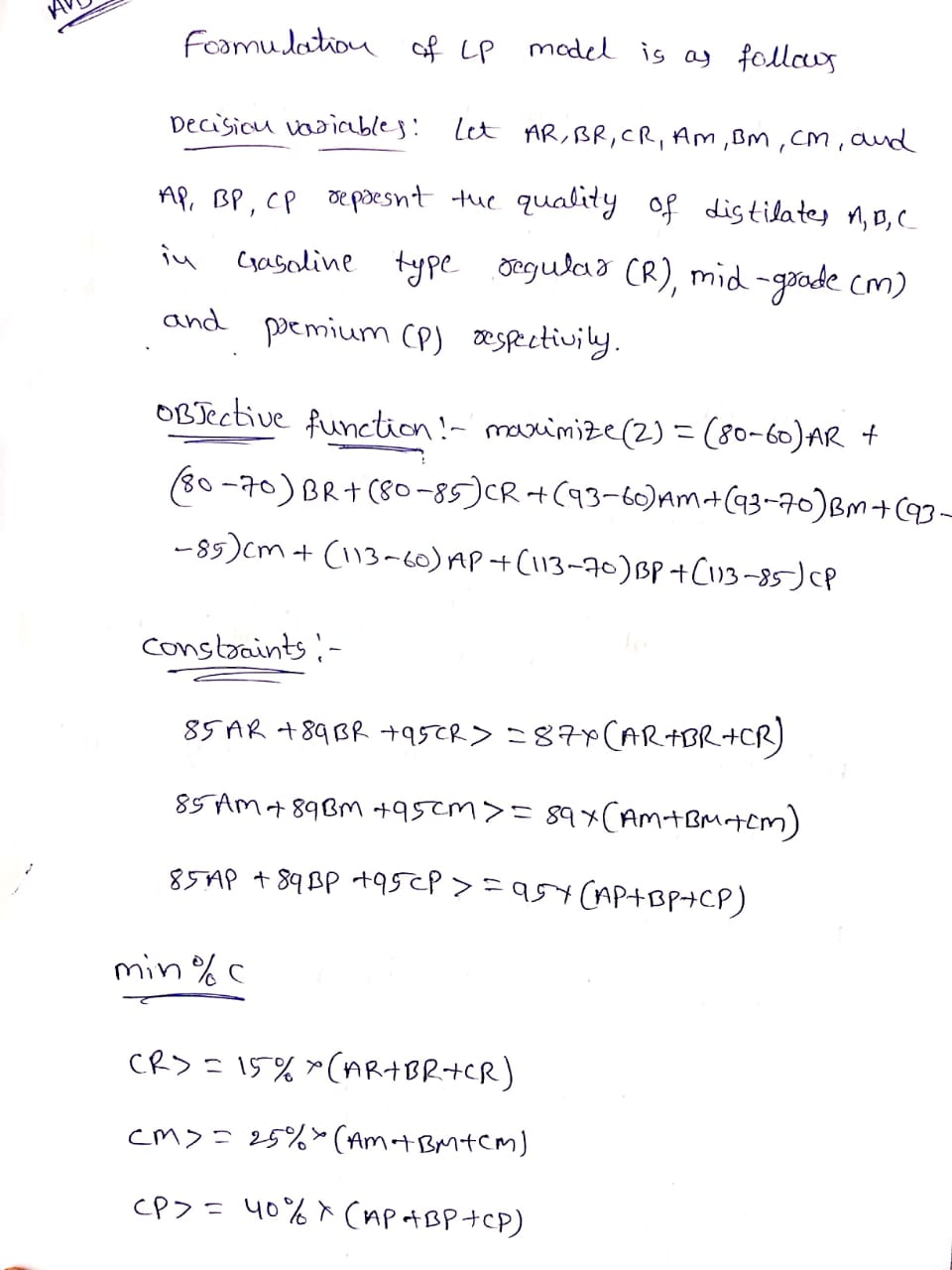

Constraints are in the statement and charts

![Blending Problems: This is another large class of problems in which linear programming is applied heavily. Blending is concerned with mixing different

materials called the constituents of the mixture (these may be chemicals, gasoline, fuels, solids, colors, foods, etc.) so that the mixture conforms to

specifications on several properties or characteristics. To model a blending problem as an LP, the linearity assumptions must hold. This implies that the

value for a characteristic for the constituents in the mixtures are the weighted average of the values of that characteristic for the constituents in the mixture;

the weights being the proportions of the constituents. As an example, consider a mixture consisting of 4 barrels of fuel 1 and 6 barrels of fuel 2, and suppose

the characteristic of interest is the octane rating (Oc.R). If linearity assumptions hold, the Oc.R of the mixture must be equal to (4 times the Oc.R of fuel 1

+ 6 times the Oc.R of fuel 2)/(4 +6). These linearity assumptions hold to a reasonable degree of precision for many important characteristics of blends of

gasolines, of crude oils, of paints, of foods, etc. That's why linear programming is used extensively in optimizing gasoline blending, in the manufacture of

paints, cattle feeds, beverages, etc. The decision variables in a blending problem are usually either the quantities or the proportions of the constituents.

Problem:

Three liquid mixtures are to be designed as provided in the table below to contain a special chemical called "Optim"

Optim [%]

45

35

65

30

Availability [gallons]

800

1000

Cost [$/gallon]

20

15

30

25

Material

700

1500

Minimum

Optim [%] Optim [%]

25

30

40

Required Amount

Igallons]

600

1200

Maximum

Selling Price ($/gallon)

70

Mixture

45

50

65

105

140

Y

900

Formulate an LP model to determine the production plan that maximizes profit.

1234](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2F388a9fab-648d-450d-a1a5-3932044f3fea%2F314a6a1d-6655-463b-8532-501b72fa5aaa%2Fdvw1zo_processed.jpeg&w=3840&q=75)

Transcribed Image Text:Blending Problems: This is another large class of problems in which linear programming is applied heavily. Blending is concerned with mixing different

materials called the constituents of the mixture (these may be chemicals, gasoline, fuels, solids, colors, foods, etc.) so that the mixture conforms to

specifications on several properties or characteristics. To model a blending problem as an LP, the linearity assumptions must hold. This implies that the

value for a characteristic for the constituents in the mixtures are the weighted average of the values of that characteristic for the constituents in the mixture;

the weights being the proportions of the constituents. As an example, consider a mixture consisting of 4 barrels of fuel 1 and 6 barrels of fuel 2, and suppose

the characteristic of interest is the octane rating (Oc.R). If linearity assumptions hold, the Oc.R of the mixture must be equal to (4 times the Oc.R of fuel 1

+ 6 times the Oc.R of fuel 2)/(4 +6). These linearity assumptions hold to a reasonable degree of precision for many important characteristics of blends of

gasolines, of crude oils, of paints, of foods, etc. That's why linear programming is used extensively in optimizing gasoline blending, in the manufacture of

paints, cattle feeds, beverages, etc. The decision variables in a blending problem are usually either the quantities or the proportions of the constituents.

Problem:

Three liquid mixtures are to be designed as provided in the table below to contain a special chemical called "Optim"

Optim [%]

45

35

65

30

Availability [gallons]

800

1000

Cost [$/gallon]

20

15

30

25

Material

700

1500

Minimum

Optim [%] Optim [%]

25

30

40

Required Amount

Igallons]

600

1200

Maximum

Selling Price ($/gallon)

70

Mixture

45

50

65

105

140

Y

900

Formulate an LP model to determine the production plan that maximizes profit.

1234

Expert Solution

Step 1

Step by step

Solved in 7 steps with 6 images

Recommended textbooks for you

Advanced Engineering Mathematics

Advanced Math

ISBN:

9780470458365

Author:

Erwin Kreyszig

Publisher:

Wiley, John & Sons, Incorporated

Numerical Methods for Engineers

Advanced Math

ISBN:

9780073397924

Author:

Steven C. Chapra Dr., Raymond P. Canale

Publisher:

McGraw-Hill Education

Introductory Mathematics for Engineering Applicat…

Advanced Math

ISBN:

9781118141809

Author:

Nathan Klingbeil

Publisher:

WILEY

Advanced Engineering Mathematics

Advanced Math

ISBN:

9780470458365

Author:

Erwin Kreyszig

Publisher:

Wiley, John & Sons, Incorporated

Numerical Methods for Engineers

Advanced Math

ISBN:

9780073397924

Author:

Steven C. Chapra Dr., Raymond P. Canale

Publisher:

McGraw-Hill Education

Introductory Mathematics for Engineering Applicat…

Advanced Math

ISBN:

9781118141809

Author:

Nathan Klingbeil

Publisher:

WILEY

Mathematics For Machine Technology

Advanced Math

ISBN:

9781337798310

Author:

Peterson, John.

Publisher:

Cengage Learning,