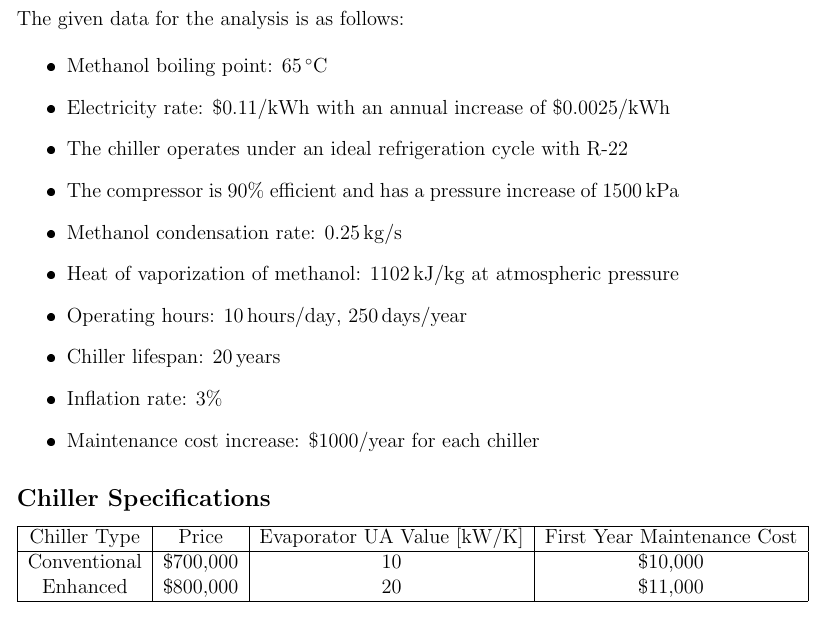

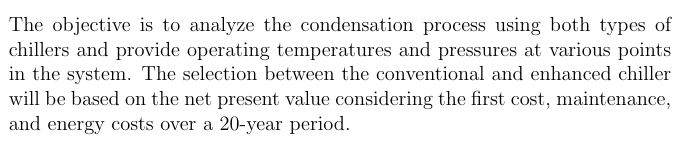

Analyze the condensation process using both chillers. Provide operating temperatures and pressures entering each component shown in the diagram (at points 1, 2, 3, 4). Indicate which chiller should be chosen based on the economics. See below for details: -Your work is replacing a chiller that is used as part of a distillation process that condenses methanol (boiling point = 65 °C). Your task is to select the most economical type of system. A conventional chiller will have a lower first cost and will have lower maintenance costs than one that involves enhanced heat transfer surfaces, but the chiller with enhanced surfaces will condense the same amount of alcohol with a lower energy consumption. Select the appropriate chiller by considering the net present value of both systems. That value will involve the first cost of the chiller, and the present value of the maintenance and energy costs. The chiller uses a standard vapor-compression refrigeration cycle with R-22 (see Figure 1). For this analysis, assume that it operates under an ideal refrigeration cycle. Electricity to run the chiller is bought by the facility at a rate of $0.11 per kWh. That rate is expected to increase at a rate of $0.0025 annually. Cycle information: o There is a sensor and controller at the inlet to the compressor that modulates the mass flow rate of refrigerant to ensure that the vapor entering the compressor is saturated. o The compressor has a flat compressor curve, meaning that the pressure increase across the compressor is insensitive to mass flow rate through it. That pressure increase is 1500 kPa. o Assume that the compressor is 90 % efficient in this operating regime. The chiller must condense methanol at a rate of 0.25 kg/s. The heat of vaporization of methanol is 1102 kJ/kg at atmospheric pressure. For any heat transfer analysis, you can assume that the methanol is at the condensation temperature (65 °C) throughout the process. The system runs 10 hours per day, 250 days per year. The chiller is projected to last 20 years, so the economic analysis should consider that time frame. Assume an inflation rate of 3 %. Maintenance costs are expected to increase at a rate of $1000 per year for each chiller. The evaporator’s UA values and other characteristics of each chiller are given. The “evaporator” of the chiller will actually be the component on which the alcohol will condense.

Analyze the condensation process using both chillers. Provide operating temperatures and

pressures entering each component shown in the diagram (at points 1, 2, 3, 4). Indicate which chiller should be chosen based on the economics.

See below for details:

-Your work is replacing a chiller that is used as part of a distillation process that condenses methanol (boiling point = 65 °C). Your task is to select the most economical type of system. A

conventional chiller will have a lower first cost and will have lower maintenance costs than one

that involves enhanced heat transfer surfaces, but the chiller with enhanced surfaces will condense the same amount of alcohol with a lower energy consumption. Select the appropriate chiller by considering the net present value of both systems. That value will involve the first cost of the chiller, and the present value of the maintenance and energy costs.

The chiller uses a standard vapor-compression refrigeration cycle with R-22 (see Figure 1). For this analysis, assume that it operates under an ideal refrigeration cycle.

Electricity to run the chiller is bought by the facility at a rate of $0.11 per kWh. That rate

is expected to increase at a rate of $0.0025 annually.

Cycle information:

o There is a sensor and controller at the inlet to the compressor that modulates the

mass flow rate of refrigerant to ensure that the vapor entering the compressor is

saturated.

o The compressor has a flat compressor curve, meaning that the pressure increase

across the compressor is insensitive to mass flow rate through it. That pressure

increase is 1500 kPa.

o Assume that the compressor is 90 % efficient in this operating regime.

The chiller must condense methanol at a rate of 0.25 kg/s. The heat of vaporization of

methanol is 1102 kJ/kg at atmospheric pressure. For any heat transfer analysis, you can assume that the methanol is at the condensation temperature (65 °C) throughout the process.

The system runs 10 hours per day, 250 days per year.

The chiller is projected to last 20 years, so the economic analysis should consider that time

frame. Assume an inflation rate of 3 %.

Maintenance costs are expected to increase at a rate of $1000 per year for each chiller.

The evaporator’s UA values and other characteristics of each chiller are given.

The “evaporator” of the chiller will actually be the component on which the alcohol will

condense.

![Chiller

Conventional

Enhanced

S

3

selan

yra

T

Price

$700,000 10

$800,000 20

Throttling valve

4

Evaporator UA

value

[kW/(K)]

Condenser

bo W 3

millet has

QE

P= constant

201

200

A

h = constant

P= constant

bcd

2

081

1

First Year Maintenance

Cost

S

$10 000

$11 000

Compressor

Evaporator

Wep](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2Ff0e69105-edad-4e40-a986-7d2af8f1b9bd%2F87c3adc6-b7fb-48b1-9a4f-71c513f09c76%2Fyytuna8_processed.jpeg&w=3840&q=75)

Step by step

Solved in 4 steps with 16 images