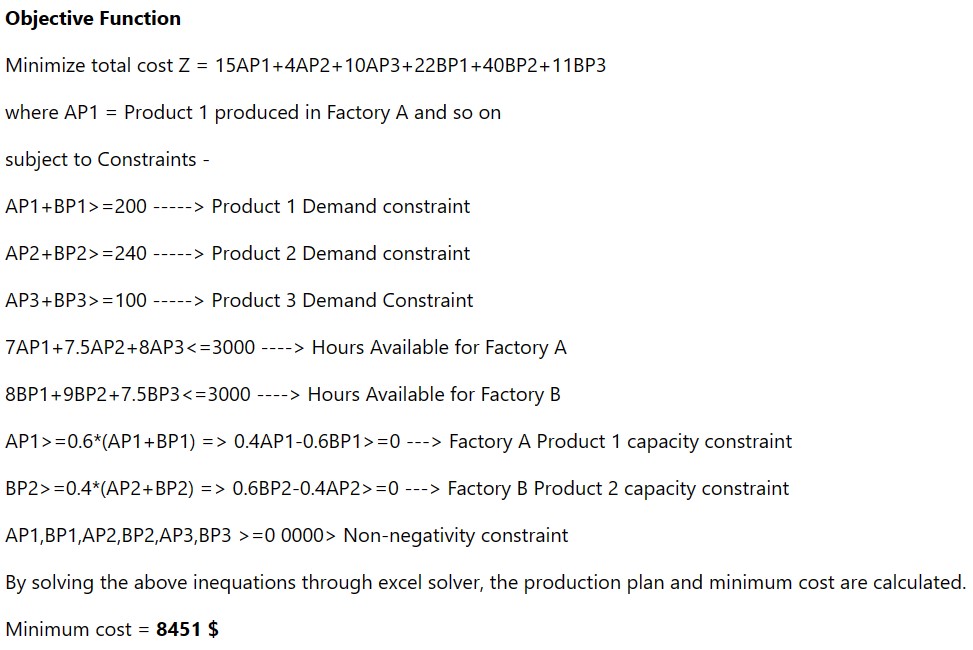

A company manufactures 3 products in 2 different factories. The cost of production and time required for production for each product varies depending on which factory produces it. The time and cost required for production of each product in each factory is provided in the tables in this worksheet. Demand for products 1, 2 and 3 are 200, 240 and 100 units, respectively. There are a total of 3,000 hours available in each factory. Additionally, at least 60% of the total units of Product 1 must be produced in Factory A, and at least 40% of of the total units of Product 2 must be produced in Factory B. Create a linear programming model and use the Solver add-in to determine the optimal production plan that will minimize total cost. Note: The cost is per unit not per hour. All demand must be met

A company manufactures 3 products in 2 different factories. The cost of production and time required for production for each product varies depending on which factory produces it.

The time and cost required for production of each product in each factory is provided in the tables in this worksheet.

Demand for products 1, 2 and 3 are 200, 240 and 100 units, respectively.

There are a total of 3,000 hours available in each factory.

Additionally, at least 60% of the total units of Product 1 must be produced in Factory A, and at least 40% of of the total units of Product 2 must be produced in Factory B.

Create a linear programming model and use the Solver add-in to determine the optimal production plan that will minimize total cost.

Note: The cost is per unit not per hour. All demand must be met.

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 3 images