6. Steam enters a pressure reducing valve at a pressure of 2000 kPa, dry saturated. It is throttled adiabatically to 100 kPa. What is the temperature and internal energy of the steam at the lower pressure. (162 °C, 2600 kJ/kg)

6. Steam enters a pressure reducing valve at a pressure of 2000 kPa, dry saturated. It is throttled adiabatically to 100 kPa. What is the temperature and internal energy of the steam at the lower pressure. (162 °C, 2600 kJ/kg)

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Cn yu do question 6

![1. A boiler feedpump receives 10 °C water at a pressure of 500 kPa. The discharge

pressure is 2 400 kPa. Given a pump capacity of 160 000 kg/h, and after correcting.

for the temperature of the water, what is the power supplied to the water? (8 kW)

2. Water is supplied to a pump at a pressure of 200 kPa. The power transferred to the

water is estimated to be 30 kW. The pump discharge pressure is 2 200 kPa and the

specific volume is 0.00106 m3/kg. Estimate the amount of water pumped in cubic

meters per min. (0.90 m3/min.)

3. Air enters a compressor with a velocity of 6.0 m/s and an enthalpy of 233 kJ/kg and

leaves with a velocity of 12 m/s and an enthalpy of 477 kJ/kg. Assuming adiabatic

compression and negligible change in potential energy, calculate the work required to

compress 1.0 kg of air. (244 kJ/kg)

4. An air compressor is supplied with air at 101.3 kPa and a specific volume of 0.804

m3/kg. The air is discharged at 700 kPa and a specific volume of 0.162 m³/kg. The

initial and final internal energies are 37.2 kJ/kg and 114 kJ/kg respectively. The

cooling water removes 88.0 kJ/kg of air compressed. The change in kinetic and

potential energy may be neglected. Calculate (a) the specific work required, (b) the

power required given a mass flow rate of 45.6 kg/min. Also (c) if the heat being

rejected is transferred to cooling water flowing through a coil, and the cooling water

picks up 10ºC across that coil, and the pump forcing that cooling flow has a 100 kPa

AP across it, calculate the power required to drive the cooling water pump (197 kJ/kg.

150 kW, 160 W)

5. Wet steam is throttled from 1000 kPa to 10 kPa and 130 °C. Find the dryness fraction

at state 1. [98.3%]

6. Steam enters a pressure reducing valve at a pressure of 2000 kPa, dry saturated. It is

throttled adiabatically to 100 kPa. What is the temperature and internal energy of the

steam at the lower pressure. (162 °C, 2600 kJ/kg)

7. A pressure reducing valve receives 5 kg/s of steam at 2MPa with a specific volume of

0.1255 m³/kg and an internal energy of 2774 kJ/kg. If the pressure downstream of

the throttle is 200 kPa and the velocity at that point is 4.25 m/s, determine to the

nearest inch the required ID of the downstream piping in order to accommodate the

volume flow rate. [54.0 inches]

DVI & Dual HDMI inputs for high-definition support

ho](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2F8f9da62a-a094-47dc-9747-5a0eb30c4375%2F853f5bb7-3b02-4367-a1b2-6142ce6b5eff%2Fztopthu_processed.jpeg&w=3840&q=75)

Transcribed Image Text:1. A boiler feedpump receives 10 °C water at a pressure of 500 kPa. The discharge

pressure is 2 400 kPa. Given a pump capacity of 160 000 kg/h, and after correcting.

for the temperature of the water, what is the power supplied to the water? (8 kW)

2. Water is supplied to a pump at a pressure of 200 kPa. The power transferred to the

water is estimated to be 30 kW. The pump discharge pressure is 2 200 kPa and the

specific volume is 0.00106 m3/kg. Estimate the amount of water pumped in cubic

meters per min. (0.90 m3/min.)

3. Air enters a compressor with a velocity of 6.0 m/s and an enthalpy of 233 kJ/kg and

leaves with a velocity of 12 m/s and an enthalpy of 477 kJ/kg. Assuming adiabatic

compression and negligible change in potential energy, calculate the work required to

compress 1.0 kg of air. (244 kJ/kg)

4. An air compressor is supplied with air at 101.3 kPa and a specific volume of 0.804

m3/kg. The air is discharged at 700 kPa and a specific volume of 0.162 m³/kg. The

initial and final internal energies are 37.2 kJ/kg and 114 kJ/kg respectively. The

cooling water removes 88.0 kJ/kg of air compressed. The change in kinetic and

potential energy may be neglected. Calculate (a) the specific work required, (b) the

power required given a mass flow rate of 45.6 kg/min. Also (c) if the heat being

rejected is transferred to cooling water flowing through a coil, and the cooling water

picks up 10ºC across that coil, and the pump forcing that cooling flow has a 100 kPa

AP across it, calculate the power required to drive the cooling water pump (197 kJ/kg.

150 kW, 160 W)

5. Wet steam is throttled from 1000 kPa to 10 kPa and 130 °C. Find the dryness fraction

at state 1. [98.3%]

6. Steam enters a pressure reducing valve at a pressure of 2000 kPa, dry saturated. It is

throttled adiabatically to 100 kPa. What is the temperature and internal energy of the

steam at the lower pressure. (162 °C, 2600 kJ/kg)

7. A pressure reducing valve receives 5 kg/s of steam at 2MPa with a specific volume of

0.1255 m³/kg and an internal energy of 2774 kJ/kg. If the pressure downstream of

the throttle is 200 kPa and the velocity at that point is 4.25 m/s, determine to the

nearest inch the required ID of the downstream piping in order to accommodate the

volume flow rate. [54.0 inches]

DVI & Dual HDMI inputs for high-definition support

ho

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 2 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

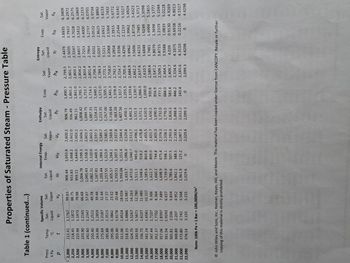

Can you please use these steam tables

Transcribed Image Text:Table 1 (continued...)

Press

k Pa

р

Properties of Saturated Steam - Pressure Table

Temp

°℃

t

Specific Volume

Sat.

Liquid

Vf

Sat.

Vapor

Vg

Note: 100k Pa = 1 Bar = 100,000N/m²

Sat.

Liquid

Uf

Internal Energy

Evap.

All

Sat.

Vapor

Ug

Enthalpy

Sat.

Liquid

hf

Evap.

Sat.

Vapor

hg

Entropy

Sat.

Liquid

Sf

Evap.

Ufg

hfg

Sfg

2,000

2,799.5

3.8935 6.3409

1,890.7

2.4474

2,799.5

2.5035

3.7937

6.2972

1,865.2

2,250

212.42 1.1767

218.45 1.1872

223.99 1.1973

233.90 1.2165

3.7028 6.2575

3.5412 6.1869

2,500

3,000

3,500

99.63

88.75

79.98

66.68

57.07

49.78

39.44

242.60 1.2347

3.4000 6.1253

3.2737 6.0701

4,000

250.40 1.2522

3.2737

3.0532 5.9734

5,000

263.99 1.2859

39.44

275.64 1.3187 32.44

2.8625 5.8892

2.6922 5.8133

285.88 1.3513

295.06 1.3842

303.40 1.4178

1,316.64

1,316.64

906.44 1,693.8 2,600.3 908.79

936.49

933.83 1,668.2 2,602.01

1,865.2 2,801.7

1,841.0 2,803.1 2.5547

959.11 1,644.0 2,603.1 962.11

1,008.42 1,795.7 2,804.2 2.6457

1,004.78 1,599.3 2,604.1

1,045.43 1,558.3 2,603.7 1,049.75 1,753.7 2,803.4

2.7253

2.7964

1,082.31 1,520.0 2,602.3 1,087.31 1,714.1 2,801.4

1,147.81 1,449.3 2,597.1 1,154.23 1,640.1 2,794.3 2.9202

1,213.35 1,571.0 2,784.3 3.0267

6,000

1,205.44 1,384.3 2,589.7

1,267.00 1,505.1 2,772.1 3.1211

7,000

27.37 1,257.55 1,323.0 2,580.5

1,441.3 2,758.0 3.2068 2.5364 5.7432

1,441.3

8,000

1,305.57 1,264.2 2,569.8

23.52

1,350.51 1,207.3 2,557.8

1,378.9 2,742.1 3.2858 2.3915 5.6772

9,000

20.48

3.3596 2.2544 5.6141

1,393.04 1,151.4 2,544.4

1,317.1 2,724.7

10,000 311.06 1.4524 18.026

3.4295 2.1233 5.5527

1,433.7 1,096.0 2,529.8

11,000 318.15 1.4886 15.987

3.4962 1.9962 5.4924

1,473.0 1,040.7 2,513.7

12,000 324.75 1.5267 14.263

13,000 330.93 1.5671 12.780 1,511.1

2,496.1 1,531.5

985.0

14,000 336.75 1.6107 11.485 1,548.6 928.2 2,476.8

15,000 342.24 1.6581 10.337 1,585.6 869.8 2,455.5

16,000 347.44 1.7107 9.306 1,622.7 809.0 2,431.7

17,000 352.37 1.7702

744.8

1,255.5

2,705.6

1,363.26

1,407.56

1,450.1

1,491.3

1,531.5

1,571.1

1,193.6

2,684.9

1,130.7

2,662.2

3.5606

1.8718

5.4323

1,066.5

2,637.6

1.7485 5.3717

1,610.5

1,000.0

2,610.5

1,650.1

2,580.6

8.364

1,660.2

2,405.0

1,690.3

1,698.9

675.4

2,374.3

1,732.0

18,000 357.06 1.8397 7.489

19,000 361.54

930.6

856.9

777.1

688.0

583.4

3.6232

3.6848 1.6249 5.3098

3.7461 1.4994 5.2455

3.8079 1.3698 5.1777

2,547.2

3.8715 1.2329 5.1044

2,509.1 3.8715

3.9388 1.0839 5.0228

2,464.5

0.9130 4.9269

4.039

2,409.7

4.1075

2,334.6

0.6938 4.8013

2,165.6 4.3110

2,099.3 4.4298

1.9243

6.657

598.1

2,338.1

1,776.5

5.834

2,293.0

20,000 365.81

21,000 369.89

2.036

2.207

1,826.3

4.952

1,739.9

1,785.6 507.5

1,842.1 388.5

125.2

1,961.9

0

1,888.4

446.2

22,000 373.80 2.742

3.568

2,230.6

2,087.1 2,022.2

2,029.6

143.4

22,090

374.14

3.155

3.155

2,029.6

0.2216 4.5327

4.4298

2,099.3

0

0

O John Wiley and Sons, Inc., Keenan, Keyes, Hill, and Moore. This material has been copied under license from CANCOPY. Resale or further

copying of this material is strictly prohibited.

Sat.

Vapor

Sg

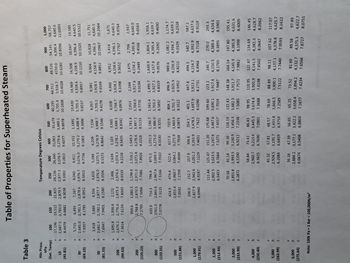

Transcribed Image Text:Table 3

Abs Press.

kPa

(Sat. Temp) 100

150

200

V v 17,196 19,512 21,825

h 2,687.5 2,783.0 2,879.5

S 8.4479 8.6882 8.9038

10

(45.81)

30

(69.10)

50

(81.33)

100

(99.63)

200

(120.23)

500

(151.86)

v

V

V 5,715 6,493

h 2,685.0

S 7.9357

h

s

V

h

300

(133.55) S

V

h

S

5,000

(263.99)

V

h

S

V

1,000 h

(179.91)

S

V

2,000 h

(212.43)

S

V

3,000 h

(233.90)

S

V

4,000 h

(250.40)

S

v

1,695.8 1,936.4 2,172 2,406

h 2,676.2 2,776.4 2,875.3 2,974.3

7.3614 7.6134 7.8343 8.0333

s

Table of Properties for Superheated Steam

V

h

S

7,267

2,781.5 2,878.6

8.3952

8.1785

V

6,000 h

(275.64) S

3,889 4,356

3,418

2,682.5

2,780.1

2,877.7

7.6947 7.9401 8.1580

Temperature Degrees Celsius

250

24,136

2,977.3

9.1002

8,040

2,976.7

8.5923

4,820

2,976.0

8.3556

***

796.4

633.9 716.3

2761.0 2,865.6 2,967.6

7.0778 7.3115 7.5166

Note: 100k Pa = 1 Bar = 100,000N/m²

232.7

206.0

2,827.9 2,942.6

6.6940 6.9247

600

700

500

400

300

26,445 31,063 35,679 40,295 44,911

3,928.7

3,076.5 3,279.6 3,489.1 3,705.4

10.4028

9.6077 9.8978 10.1608

9.2813

959.6 1,080.3 1,198.8 1,316.2

2,768.8 2,870.5 2,971.0 3,071.8

7.2795 7.5066 7.7086 7.8926

7.8926

8,811

3,076.0

8.7736

5,284

3,075.5

8.5373

2,639

3,074.3

8.2158

424.9 474.4 522.6

2,855.4 2,960.7 3,064.2

7.0592

7.2709

7.2709 7.4599

10,351

3,279.2

9.1003

111.44 125.47

2,902.5 3,023.5

6.5453 6.7664

6,209

3,278.9

8.8642

70.58 81.14

2,855.8 2,993.5

6.2872 6.5390

3,103

3,278.2

8.5435

875.3 1,031.5 1,186.7

3,069.3 3,275.0

7.7022 8.0330

3,486.0

8.3251

257.9 306.6

3,263.9

3,051.2

7.1229

7.4651

617.3

3,271.9

7.7938

1,1891

3,488.9

9.3906

99.36

3,230.9

6.9212

58.84

73.41

2,960.7 3,213.6

6.3615

6.7690

7,134

7,134 8,057

8,057

3,488.7

3,705.1

9.1546

9.4178

3,565

4,028

3,488.1

3,704.7

8.8342 9.0976

1,549.3 1,781.4 2,013 2,244

3,276.6 3,487.1 3,704.0

8.2218 8.5133 8.7770

3,927.6

9.0194

36.16

6.0674

2,884.2 3,177.2

710.9

3,483.9

8.0873

13,430

3,705.3

9.6537

354.1

3,478.5

7.7622

151.20 175.68

199.60

3,247.6 3,467.6 3,690.1

3,247.6

7.1271 7.4317

7.7024

86.43

3,445.3

7.0901

45.32 57.81

68.57

2,924.5 3,195.7 3,433.8

6.2084 6.6459

6.9759

1,341.4

3,703.2

8.5892

804.1

3,701.7

8.3522

401.1

3,697.9

8.0290

116.19 132.43

3,456.5

3,682.3

7.2338

7.5085

98.95

3,674.4

3,674.4

7.3688

78.69

3,666.5

7.2589

65.25

47.39 56.65

3,422.2

6.5408 6.8803 7.1677

3,658.4

14,969

3,928.6

19,585

16,508 18,047

4,158.9 4,396.4 4,640.5

9.8957 10.1210 10.3325 10.5322

8,981 9,904 10,828 11,751

3,928.5 4,158.9 4,396.3 4,640.5

9.6599 9.8852 10.0967 10.2964

9.6599

4,490

3,928.2

9.3398

1,495.7

3,927.1

8.8319

896.9

3,925.9

8.5952

447.8

3,923.1

8.2731

223.2

3,917.4

7.9487

800

900

1,000

49,526 54,141 58,757

4159.0 4,396.4 4,640.6

10.6281 10.8396 11.0393

110.95

3,905.9

7.6198

88.49

3,900.1

7.5122

4,952 5,414 5,875

4,158.6

4,396.1

4,640.3

9.5652

9.7767

9.9764

2,475

4,158.2

9.2449

1,649.9 1,804.1

1,958.1

4,157.8 4,395.4 4,639.7

9.0576

9.2692

9.2692 9.4690

989.6 1,082.2 1,174.7

4,156.9

4,394.7

4,639.1

8.8211

9.0329

9.2328

2,706

2,937

4,395.8

4,395.8 4,640.0

9.4566

9.6563

246.7

4,150.3

8.1765

494.3

4,154.7

8.4966 8.7118

148.38

3,911.7

7.7571 7.9862 8.1999 8.4009

164.14 197.80 195.41

4,145.9 4,385.9 4,631.6

122.87

4,141.5

7.8502

540.7 587.1

4,392.9 4,637.6

8.7118 8.9119

98.11

4,137.1

7.7440

270.0

293.3

4,389.4 4,634.6

8.3895 8.5901

134.69 146.45

4,382.3 4,628.7

8.0647 8.2662

107.62 117.07

4,378.8 4,625.7

7.9593 8.1612

73.52

89.58 97.49

81.60

4,132.7 4,375.3 4,622.7

3,894.2

7.4234 7.6566 7.8727 8.0751

Solution

Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY