2. The component shown always breaks at point C, which is just to the right of the contact point of the roller at B. Find the internal forces in terms of shear, normal and bending to show why this is. 150 mm -250 mm- 400 N A OB 125 mm 500 N 110 mm 80 N•m

2. The component shown always breaks at point C, which is just to the right of the contact point of the roller at B. Find the internal forces in terms of shear, normal and bending to show why this is. 150 mm -250 mm- 400 N A OB 125 mm 500 N 110 mm 80 N•m

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

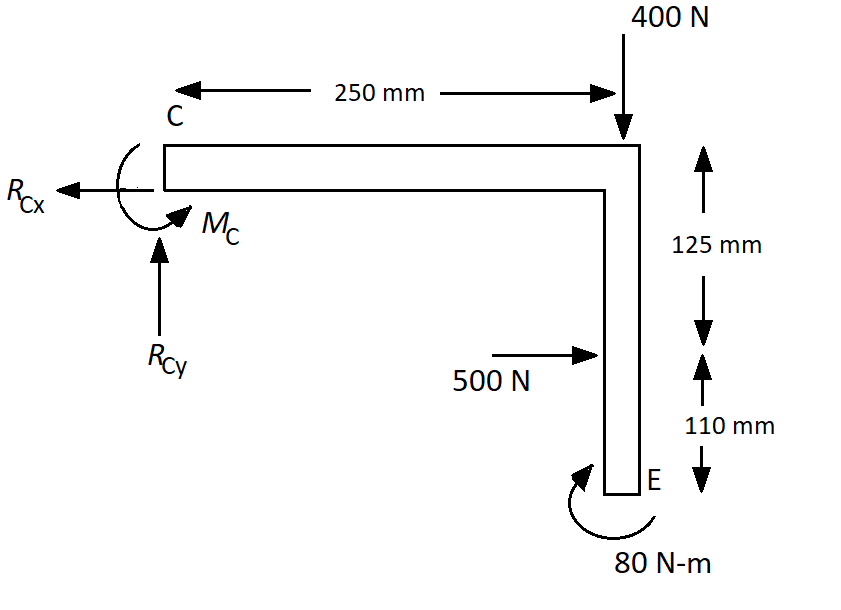

Transcribed Image Text:### Problem Description

The component shown always breaks at point C, which is just to the right of the contact point of the roller at B. Find the internal forces in terms of shear, normal, and bending to show why this is.

### Diagram Explanation

- **Diagram Overview**: The diagram depicts an L-shaped beam subjected to various forces and moments.

- **Beam Structure**:

- The horizontal arm extends 400 mm from point A through point B to point C.

- The vertical section starts at the end of the horizontal arm at C and extends downward.

- The beam makes an L-shape at the corner where it turns downwards.

- **Forces and Dimensions**:

- **Support at A**: A fixed support (triangle symbol) is indicated, which can prevent both translation and rotation.

- **Roller at B**: A roller support is present, which allows for horizontal movement. It is positioned 150 mm from A.

- **External Forces**:

- **400 N**: A downward force acts vertically at point C.

- **500 N**: A horizontal force acts to the right on the vertical section, 125 mm below point C.

- **80 N·m**: A clockwise moment is applied at the bottom of the vertical section.

- **Distances**:

- The distance from A to B is 150 mm, while from B to C is 250 mm.

- The vertical section is 110 mm.

### Task

Calculate the internal forces at the beam's critical point, C:

- **Shear Force**: Analyze forces causing sliding failure along the beam cross-section.

- **Normal Force**: Measure axial forces affecting the beam.

- **Bending Moment**: Evaluate moment forces causing the beam to bend and potentially fail.

### Objective

Determine why breaking consistently occurs at point C, just past the roller. Analyze the contributing internal forces to explain this failure location.

Expert Solution

Step 1

The component always breaks at point C, which is just right of the contact point of the roller at B. So, draw the free-body diagram of the section which is just right of the contact point of the roller at B as follows:

Here, the reaction force at C in the horizontal direction is RCx, the reaction force at C in the vertical direction is RCy and the moment reaction at C is MC.

Step 2

Consider the equilibrium of force in the horizontal direction,

Consider the equilibrium of force in the vertical direction,

Calculate the moment reaction at C,

Step 3

Therefore, the internal forces in terms of shear, normal, and bending are,

Step by step

Solved in 5 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY