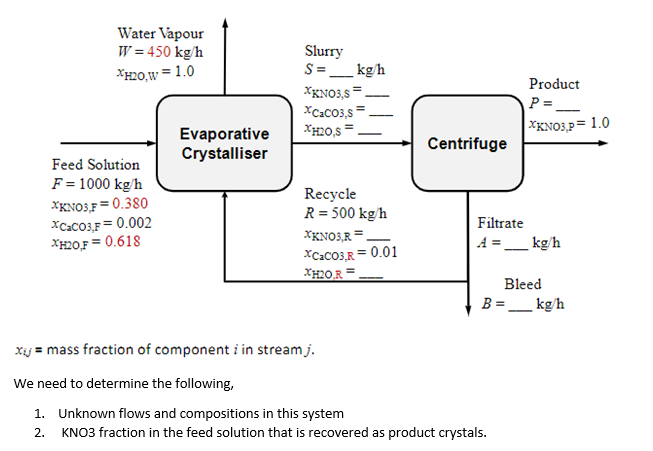

1000 kg/h of an aqueous feed solution containing 38 wt.% potassium nitrate (KNO3) and 0.2 wt.% CaCO3 (the rest is water) is crystallised in an evaporative crystalliser. 450 kg/h of water vapour are evaporated from the crystalliser to create a super‐saturated solution which then causes crystals to form and grow. The product crystal slurry is then fed to a centrifuge where perfectly dry KNO3 crystals are recovered.1 The filtrate solution (which still contains some dissolved KNO3 as well as dissolved CaCO3) is recycled back to the crystalliser. However, a bleed (purge) stream is split off and removed in order to keep the concentration of CaCO3 in the return solution from climbing above 1 wt.% (in order to prevent crystallisation of CaCO3 when its concentration builds up too high). Once this bleed is removed, the remaining 500 kg/h of solution is recycled. See diagram. Determine: 1. Unknown flows and compositions in this system. 2. KNO3 fraction in the feed solution that is recovered as product crystals.

1000 kg/h of an aqueous feed solution containing 38 wt.% potassium nitrate (KNO3) and 0.2 wt.%

CaCO3 (the rest is water) is crystallised in an evaporative crystalliser. 450 kg/h of water vapour are

evaporated from the crystalliser to create a super‐saturated solution which then causes crystals to

form and grow. The product crystal slurry is then fed to a centrifuge where perfectly dry KNO3

crystals are recovered.1 The filtrate solution (which still contains some dissolved KNO3 as well as

dissolved CaCO3) is recycled back to the crystalliser. However, a bleed (purge) stream is split off and

removed in order to keep the concentration of CaCO3 in the return solution from climbing above 1

wt.% (in order to prevent crystallisation of CaCO3 when its concentration builds up too high). Once

this bleed is removed, the remaining 500 kg/h of solution is recycled. See diagram.

Determine:

1. Unknown flows and compositions in this system.

2. KNO3 fraction in the feed solution that is recovered as product crystals.

Step by step

Solved in 4 steps with 9 images