Fox And Mcdonald's Introduction To Fluid Mechanics

9th Edition

ISBN: 9781118921876

Author: Pritchard, Philip J.; Leylegian, John C.; Bhaskaran, Rajesh

Publisher: WILEY

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 2, Problem 66P

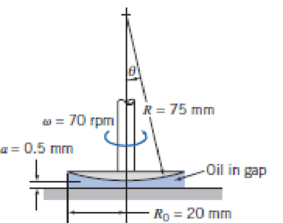

A cross section of a rotating bearing is shown. The spherical member rotates with angular speed ω, a small distance, a, above the plane surface. The narrow gap is filled with viscous oil, having μ = 1250 cp. Obtain an algebraic expression for the shear stress acting on the spherical member. Evaluate the maximum shear stress that acts on the spherical member for the conditions shown. (Is the maximum necessarily located at the maximum radius?) Develop an algebraic expression (in the form of an integral) for the total viscous shear torque that acts on the spherical member. Calculate the torque using the dimensions shown.

P2.66

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

Quick solution required.

My request, Don't use Ai.

Mechanical engineering

Please give handwritten solution, don't use chatgpt.

Fbd should be included

(I) [40 Points] Using centered finite difference approximations as done in class, solve the equation for O:

d20

dx²

+ 0.010+ Q=0

subject to the boundary conditions shown in the stencil below. Do this for two values of Q: (a) Q = 0.3,

and (b) Q= √(0.5 + 2x)e-sinx (cos(5x)+x-0.5√1.006-x| + e −43*|1+.001+x* | * sin (1.5 − x) +

(cosx+0.001 + ex-1250+ sin (1-0.9x)|) * x - 4.68x4. For Case (a) (that is, Q = 0.3), use the stencil in Fig.

1. For Case (b), calculate with both the stencils in Fig. 1 and Fig 2. For all the three cases, show a table as

well as a plot of O versus x. Discuss your results. Use MATLAB and hand in the MATLAB codes.

1

0=0

x=0

2

3

4

0=1

x=1

Fig 1

1 2 3 4 5 6 7 8 9 10

11

0=0

x=0

0=1

x=1

Fig 2

Chapter 2 Solutions

Fox And Mcdonald's Introduction To Fluid Mechanics

Ch. 2 - For the velocity fields given below, determine:...Ch. 2 - For the velocity fields given below, determine:...Ch. 2 - A viscous liquid is sheared between two parallel...Ch. 2 - For the velocity field V=Ax2yi+Bxy2j, where A = 2...Ch. 2 - A fluid flow has the following velocity...Ch. 2 - When an incompressible, nonviscous fluid flows...Ch. 2 - For the free vortex flow the velocities are t =...Ch. 2 - For the forced vortex flow the velocities are t =...Ch. 2 - A velocity field is specified as V=axyi+by2j,...Ch. 2 - A velocity field is given by V=ax3i+bxy3j, where a...

Ch. 2 - The velocity for a steady, incompressible flow in...Ch. 2 - The flow field for an atmospheric flow is given by...Ch. 2 - For the velocity field V=AxiAyj,, where A = 2s 1....Ch. 2 - A velocity field in polar coordinates is given...Ch. 2 - The flow of air near the Earths surface is...Ch. 2 - A velocity field is given by V=aytibxj, where a =...Ch. 2 - Air flows downward toward an infinitely wide...Ch. 2 - Consider the flow described by the velocity field...Ch. 2 - Consider the velocity field V = axi + by(1 + ct)...Ch. 2 - Consider the flow field given in Eulerian...Ch. 2 - A velocity field is given by V=axti+byj, where A =...Ch. 2 - Consider the garden hose of Fig. 2.5. Suppose the...Ch. 2 - Consider the velocity field of Problem 2.18. Plot...Ch. 2 - Streaklines are traced out by neutrally buoyant...Ch. 2 - Consider the flow field V=axti+bj, where a = 1/s2...Ch. 2 - A flow is described by velocity field V=ay2i+bj,...Ch. 2 - Tiny hydrogen bubbles are being used as tracers to...Ch. 2 - A flow is described by velocity field V=ai+bxj,...Ch. 2 - A flow is described by velocity field V=ayi+btj,...Ch. 2 - A flow is described by velocity field V=ati+bj,...Ch. 2 - The variation with temperature of the viscosity of...Ch. 2 - The variation with temperature of the viscosity of...Ch. 2 - Some experimental data for the viscosity of helium...Ch. 2 - The velocity distribution for laminar flow between...Ch. 2 - What is the ratio between the viscosities of air...Ch. 2 - Calculate velocity gradients and shear stress for...Ch. 2 - A very large thin plate is centered in a gap of...Ch. 2 - A female freestyle ice skater, weighing 100 lbf,...Ch. 2 - A block of mass 10 kg and measuring 250 mm on each...Ch. 2 - A 73-mm-diameter aluminum (SG = 2.64) piston of...Ch. 2 - A vertical gap 25 mm wide of infinite extent...Ch. 2 - A cylinder 8 in. in diameter and 3 ft long is...Ch. 2 - Crude oil at 20C fills the space between two...Ch. 2 - The piston in Problem 2.40 is traveling at...Ch. 2 - A block of mass M slides on a thin film of oil....Ch. 2 - A block 0.1 m square, with 5 kg mass, slides down...Ch. 2 - A torque of 4 N m is required to rotate the...Ch. 2 - A circular disk of diameter d is slowly rotated in...Ch. 2 - The fluid drive shown transmits a torque T for...Ch. 2 - A block that is a mm square slides across a flat...Ch. 2 - In a food-processing plant, honey is pumped...Ch. 2 - SAE 10W-30 oil at 100C is pumped through a tube L...Ch. 2 - The lubricant has a kinematic viscosity of 2:8105...Ch. 2 - Calculate the approximate viscosity of the oil....Ch. 2 - Calculate the approximate power lost in friction...Ch. 2 - Fluids of viscosities 1 = 0.1 Ns/m2 and 2 = 0.15...Ch. 2 - A concentric cylinder viscometer may be formed by...Ch. 2 - A concentric cylinder viscometer is driven by a...Ch. 2 - A shaft with outside diameter of 18 mm turns at 20...Ch. 2 - A shock-free coupling for a low-power mechanical...Ch. 2 - A proposal has been made to use a pair of parallel...Ch. 2 - The cone and plate viscometer shown is an...Ch. 2 - A viscometer is used to measure the viscosity of a...Ch. 2 - A concentric-cylinder viscometer is shown. Viscous...Ch. 2 - Design a concentric-cylinder viscometer to measure...Ch. 2 - A cross section of a rotating bearing is shown....Ch. 2 - Small gas bubbles form in soda when a bottle or...Ch. 2 - You intend to gently place several steel needles...Ch. 2 - According to Folsom [6], the capillary rise h...Ch. 2 - Calculate and plot the maximum capillary rise of...Ch. 2 - Calculate the maximum capillary rise of water...Ch. 2 - Calculate the maximum capillary depression of...Ch. 2 - Water usually is assumed to be incompressible when...Ch. 2 - The viscous boundary layer velocity profile shown...Ch. 2 - In a food industry process, carbon tetrachloride...Ch. 2 - What is the Reynolds number of water at 20C...Ch. 2 - A supersonic aircraft travels at 2700 km/hr at an...Ch. 2 - SAE 30 oil at 100C flows through a 12-mm-diameter...Ch. 2 - A seaplane is flying at 100 mph through air at...Ch. 2 - An airliner is cruising at an altitude of 5.5 km...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Fig 2 (II) [60 Points] Using centered finite difference approximation as done in class, solve the equation: 020 020 + მx2 მy2 +0.0150+Q=0 subject to the boundary conditions shown in the stencils below. Do this for two values of Q: (a) Q = 0.3, and (b) Q = 10.5x² + 1.26 * 1.5 x 0.002 0.008. For Case (a) (that is, Q = 0.3) use Fig 3. For Case (b), use both Fig. 3 and Fig 4. For all the three cases, show a table as well as the contour plots of versus (x, y), and the (x, y) heat flux values at all the nodes on the boundaries x = 1 and y = 1. Discuss your results. Use MATLAB and hand in the MATLAB codes. (Note that the domain is (x, y)e[0,1] x [0,1].) 0=0 0=0 4 8 12 16 10 Ꮎ0 15 25 9 14 19 24 3 11 15 0=0 8-0 0=0 3 8 13 18 23 2 6 сл 5 0=0 10 14 6 12 17 22 1 6 11 16 21 13 e=0 Fig 3 Fig 4 Textbook: Numerical Methods for Engineers, Steven C. Chapra and Raymond P. Canale, McGraw-Hill, Eighth Edition (2021).arrow_forwardShip construction question. Sketch and describe the forward arrangements of a ship. Include componets of the structure and a explanation of each part/ term. Ive attached a general fore end arrangement. Simplfy construction and give a brief describion of the terms.arrow_forwardProblem 1 Consider R has a functional relationship with variables in the form R = K xq xx using show that n ✓ - (OR 1.) = i=1 2 Их Ux2 Ихэ 2 (177)² = ² (1)² + b² (12)² + c² (1)² 2 UR R x2 x3arrow_forward

- 4. Figure 3 shows a crank loaded by a force F = 1000 N and Mx = 40 Nm. a. Draw a free-body diagram of arm 2 showing the values of all forces, moments, and torques that act due to force F. Label the directions of the coordinate axes on this diagram. b. Draw a free-body diagram of arm 2 showing the values of all forces, moments, and torques that act due to moment Mr. Label the directions of the coordinate axes on this diagram. Draw a free body diagram of the wall plane showing all the forces, torques, and moments acting there. d. Locate a stress element on the top surface of the shaft at A and calculate all the stress components that act upon this element. e. Determine the principal stresses and maximum shear stresses at this point at A.arrow_forward3. Given a heat treated 6061 aluminum, solid, elliptical column with 200 mm length, 200 N concentric load, and a safety factor of 1.2, design a suitable column if its boundary conditions are fixed-free and the ratio of major to minor axis is 2.5:1. (Use AISC recommended values and round the ellipse dimensions so that both axes are whole millimeters in the correct 2.5:1 ratio.)arrow_forward1. A simply supported shaft is shown in Figure 1 with w₁ = 25 N/cm and M = 20 N cm. Use singularity functions to determine the reactions at the supports. Assume El = 1000 kN cm². Wo M 0 10 20 30 40 50 60 70 80 90 100 110 cm Figure 1 - Problem 1arrow_forward

- Please AnswerSteam enters a nozzle at 400°C and 800 kPa with a velocity of 10 m/s and leaves at 375°C and 400 kPa while losing heat at a rate of 26.5 kW. For an inlet area of 800 cm2, determine the velocity and the volume flow rate of the steam at the nozzle exit. Use steam tables. The velocity of the steam at the nozzle exit is m/s. The volume flow rate of the steam at the nozzle exit is m3/s.arrow_forward2. A support hook was formed from a rectangular bar. Find the stresses at the inner and outer surfaces at sections just above and just below O-B. -210 mm 120 mm 160 mm 400 N B thickness 8 mm = Figure 2 - Problem 2arrow_forwardSteam flows steadily through a turbine at a rate of 45,000 lbm/h, entering at 1000 psia and 900°F and leaving at 5 psia as saturated vapor. If the power generated by the turbine is 4.1 MW, determine the rate of heat loss from the steam. The enthalpies are h1 = 1448.6 Btu/lbm and h2 = 1130.7 Btu/lbm. The rate of heat loss from the steam is Btu/s.arrow_forward

- The A/D converter wit the specifications listed below is planned to be used in an environment in which the A/D converter temperature may change by ± 10 °C. Estimate the contributions of conversion and quantization errors to the uncertainty in the digital representation of an analog voltage by the converter. FSO N Linearity error Temperature drift error Analog to Digital (A/D) Converter 0-10 V 12 bits ± 3 bits 1 bit/5 °Carrow_forward6-13. A smooth tube in the form of a circle of radius r rotates in its vertical plane with a constant angular velocity w. The position of a particle of mass m that slides inside the tube is given by the relative coordinate p. Find the differential equation for . e О E g ω Figure P6-13arrow_forwardProblem 2 Consider the power drawn by a resistance load in a DC circuit. The power is calculated as P = VI or P = 1²R. It is given that the normalized uncertainty or % percentage uncertainty in measurements of I, R, and V are the same. Find the uncertainty in P using the two different expressions for power. Is the uncertainty using the two methods the same? If not, WHY, explain?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY

Introduction to Kinematics; Author: LearnChemE;https://www.youtube.com/watch?v=bV0XPz-mg2s;License: Standard youtube license