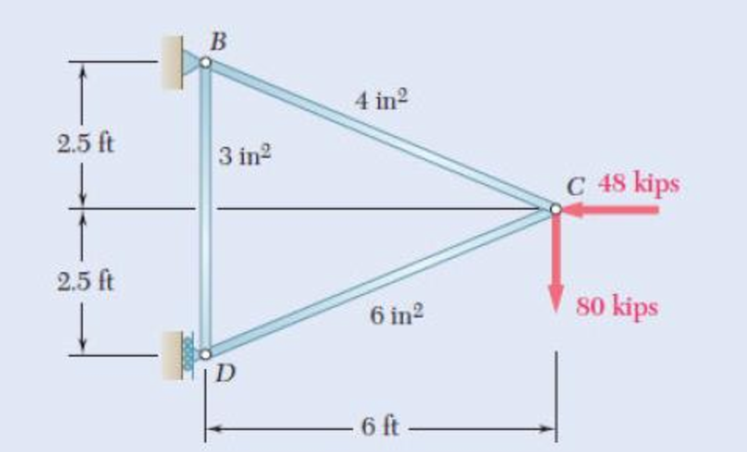

11.101 and 11.102 Each member of the truss shown is made of steel and has the cross-sectional area shown. Using E = 29 × 106 psi, determine the deflection indicated.

11.101 Vertical deflection of joint C.

11.102 Horizontal deflection of joint C.

Fig. P11.101 and P11.102

Calculate the horizontal deflection of joint C

Answer to Problem 102P

The horizontal deflection of joint C

Explanation of Solution

Given information:

The Young’s modulus of the steel (E) is

The area of the member BC

The area of the member BD

The area of the member CD

The vertical load act at the joint C (P) is

The horizontal load act at the joint C (G) is

The length of the member BD

The length of the member (L) is

Calculation:

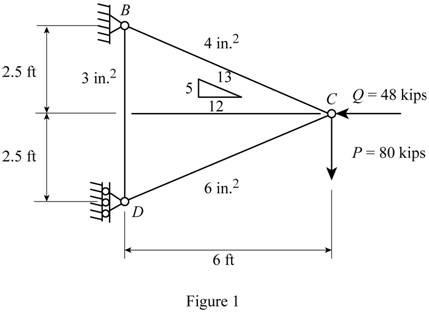

Show the free body diagram of the truss members as in Figure 1.

Refer to Figure 1.

The length of the member BC

The length of the member CD

The length of the member BD

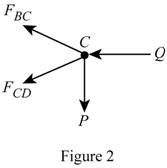

Show the diagram of the joint C as in Figure 2.

Here,

Refer to Figure 2.

Calculate the horizontal forces by applying the equation of equilibrium:

Sum of horizontal forces is equal to 0.

Calculate the vertical forces by applying the equation of equilibrium:

Sum of vertical forces is equal to 0.

Calculate the force act at the member CD

Substitute

Calculate the force act at the member BC

Substitute

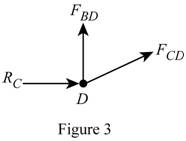

Show the diagram of the joint D as in Figure 3.

Here,

Refer to Figure 3.

Calculate the vertical forces by applying the equation of equilibrium:

Sum of vertical forces is equal to 0.

Substitute

Partial differentiate the force act at the member BC

Calculate the deflection of the member BC

Substitute

Partial differentiate the force act at the member CD

Calculate the deflection of the member CD

Substitute

Partial differentiate the force act at the member BD

Calculate the strain energy of the member BD

Substitute

Calculate the vertical deflection of joint C

Substitute

Substitute

Hence the horizontal deflection of joint C

Want to see more full solutions like this?

Chapter 11 Solutions

EBK MECHANICS OF MATERIALS

- In the system shown in the (img 1), water flows through the pump at a rate of 50L/s. The permissible NPSH providedby the manufacturer with that flow is 3.6 m. Determine the maximum height Delta z above the water surface at which the Pump can be installed to operate without cavitation. Include all losses in the suction tube. What is the value of the smaller total losses? What is the value of minor-minor losses? What is the value of major-minor losses?arrow_forwardA plastic canister whose bottom surface can be approximated as a flat surface1.9 m and 3 m long, travels through the water at 19 °C with a speed of up to 48 km/h. Determine: Drag due to friction that water exerts on the boat The power needed to overcome itarrow_forward(Fig. 1) shows the performance of a centrifugal pump for various diameters of theimpeller. For such a pump with a 5" diameter impeller, what power, in hp, would be expected to supply 5 L/s?what is its efficiency, in %?A pumping system requires 6 L/s of water with a load of 8 m, which of the pumpsof (fig. 1) would you recommend for this application?;arrow_forward

- You have the following information about a ship (image 1) Determine:a) Calculation of the block coefficient. b) Calculation of the wake coefficient. c) Determine the length of the wake.arrow_forwardA stainless steel canoe moves horizontally along the surface of a lake at 3.7 mi/h. TheThe lake's water temperature is 60°F. The bottom of the canoe is 25 ft long and flat. The boundary layer inThe bottom of the canoe is laminar or turbulent. the value of kinematic viscosity is? the value of the Reynolds number is?arrow_forwardExample Example 1 A vertical tubular test section is to be installed in an experimental high pressure water loop. The tube is 10.16 mm i.d. and 3.66 m long heated uniformly over its EXAMPLE 73 length. An estimate of the pressure drop across the test section is required as a function of the flow-rate of water entering the test section at 204°C and 68.9 bar. (1) Calculate the pressure drop over the test section for a water flow of 0.108 kg/s with a power of 100 kW applied to the tube using (i) the homogeneous model (ii) the Martinelli-Nelson model (iii) The Thom correlation (iv) the Baroczy correlation (2) Estimate the pressure drop versus flow-rate relationship over the range 0.108 to 0.811 kg/s (2-15 USGPM) for a power of 100 kW and 200 kW applied to the tube using (i) the Martinelli-Nelson model (ii) the Baroczy correlationarrow_forward

- "A seismograph detects vibrations caused by seismic movements. To model this system, it is assumed that the structure undergoes a vibration with a known amplitude band frequency w (rad/s), such that its vertical displacement is given by xB=bsin(wt). This movement of the structure will produce a relative acceleration in the mass m of 2 kg, whose displacement 2 will be plotted on a roller." x= 15 kN/m Structure -WI 24 mm (Ctrl) sin(wt) b(w/w)² √√1 (w/w)] + [25(w/w)]²' "The seismograph's roller measures 60 mm, and a maximum vibration amplitude of the structure of b<5 mm is expected. Design the damper (constant c) to ensure that, for a constant oscillation, the seismograph functions correctly and the needle does not move off the roller."arrow_forwardAircraft B is traveling at a steady speed of VB = 400 mi/hr at an altitude of 6000 ft. Meanwhile, when aircraft A is at an altitude of 10,000 ft, the line connecting A to B lies in the vertical plane of B's flight path and forms an angle of 0 = 30 degrees with the vertical. Assuming A maintains a constant velocity, find the speed required for a collision to occur. Additionally, calculate the time it would take for the collision to happen after both aircraft reach the described positions, provided no evasive measures are taken. Problem outline: 1- Find the velocity of A for the collision to happen. 2- Find the time at which the collision happens. 3- Explain the solution process with your own words. - 10,000 ft 12° 6000 ft B UBarrow_forwardDetermine the gross take-off weight of the aircraftarrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY